Ultra Sounds Improve Precision Drilling in Glass

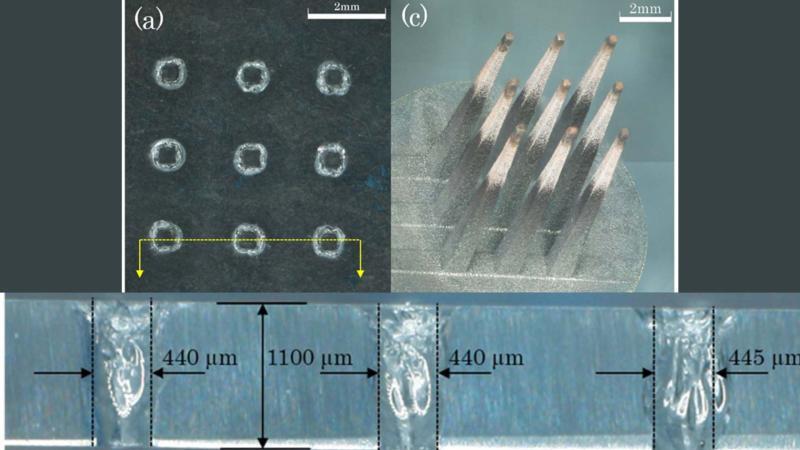

Drilling precise microholes in brittle materials like glass has long been a challenge in the manufacturing industry. The process is crucial for creating microfluidic devices, 3D sensors, and other components that require high precision and accuracy. However, traditional drilling methods often result in low efficiency, poor surface finish, and even damage to the material. Recently, researchers from IIT Bombay have made a breakthrough in this area, demonstrating the superiority of Ultrasonic-Assisted Electrochemical Discharge Machining (UA-ECDM) for drilling deep microholes in brittle glass.

The UA-ECDM technique involves the use of ultrasonic vibrations to enhance the drilling process. According to the researchers, the ultrasonic vibrations act like a plunger, significantly improving the efficiency of debris removal. This results in a 50% increase in debris removal efficiency, making the process more precise and efficient. The study, which was conducted by the researchers, aimed to investigate the mechanism of UA-ECDM and optimize the parameters for drilling deep microholes in brittle glass.

The researchers explained that the traditional electrochemical discharge machining (ECDM) process is limited by the inefficient removal of debris, which can lead to clogging and damage to the material. The introduction of ultrasonic vibrations in the UA-ECDM process overcomes this limitation by creating a continuous flow of electrolyte, which helps to remove the debris more efficiently. This results in a significant improvement in the drilling rate, surface finish, and overall precision of the process.

The study also investigated the effect of various parameters, such as ultrasonic frequency, voltage, and electrolyte concentration, on the drilling process. The researchers found that optimizing these parameters is crucial for achieving the best results. They also developed a model to predict the drilling rate and surface roughness based on these parameters, which can be used to optimize the process for specific applications.

The breakthrough achieved by the IIT Bombay researchers has significant implications for the manufacturing industry. The UA-ECDM technique can be used to create complex microstructures and 3D components with high precision and accuracy. This can lead to the development of new microfluidic devices, 3D sensors, and other components that require high precision and accuracy.

The researchers also highlighted the potential of the UA-ECDM technique for drilling deep microholes in other brittle materials, such as ceramics and silicon. This can open up new possibilities for the manufacturing of complex components and devices in these materials.

In conclusion, the study by IIT Bombay researchers has demonstrated the superiority of UA-ECDM for drilling deep microholes in brittle glass. The technique offers a significant improvement in precision, efficiency, and surface finish compared to traditional drilling methods. The optimal settings for the technique, as developed by the researchers, can be used to manufacture microfluidic and 3D sensor components with high precision and accuracy.

The study is a significant breakthrough in the field of manufacturing and has the potential to revolutionize the way we create complex microstructures and 3D components. As the demand for microfluidic devices, 3D sensors, and other components continues to grow, the UA-ECDM technique is likely to play a crucial role in meeting this demand.

For more information on this study, please visit: https://researchmatters.in/news/new-study-reveals-how-ultrasonic-vibration-solves-microhole-drilling-problem-brittle-materials