Scientists develop metal tubes that could enable unsinkable ships

The concept of an “unsinkable ship” has long been a topic of fascination and debate among engineers, scientists, and maritime enthusiasts. While the idea may seem like the stuff of science fiction, a recent breakthrough in materials science has brought us one step closer to making this vision a reality. A team of scientists has developed a revolutionary new material that could potentially be used to build ships that are virtually unsinkable.

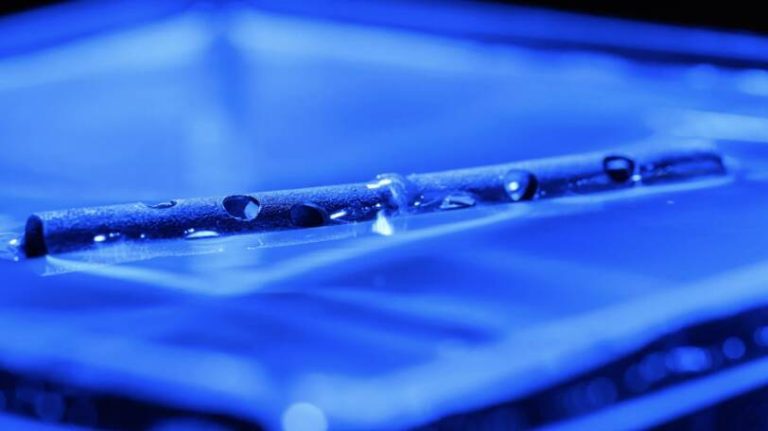

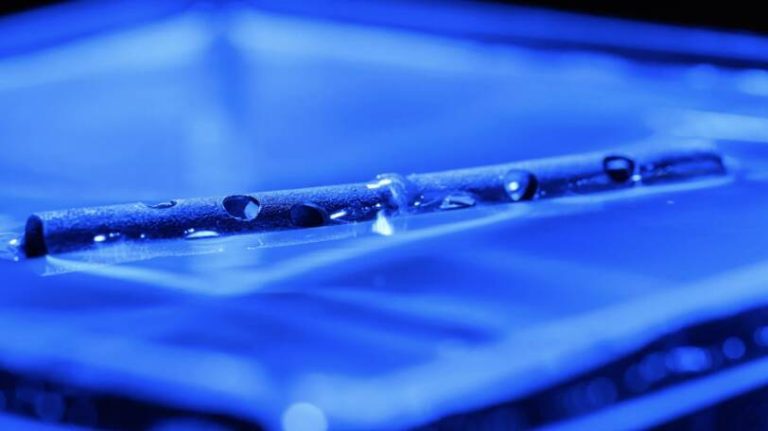

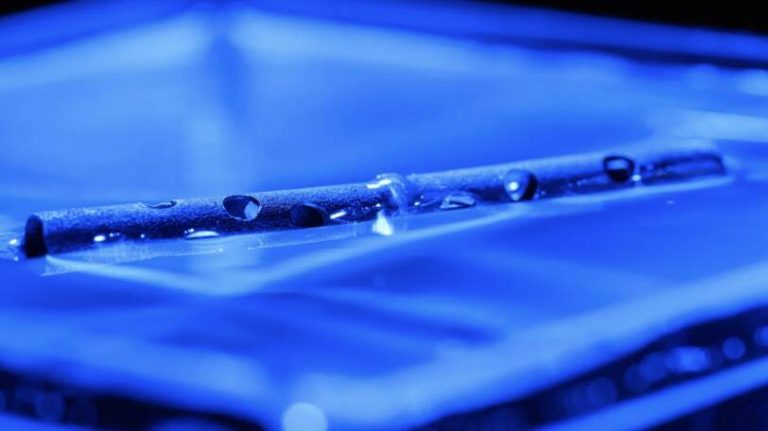

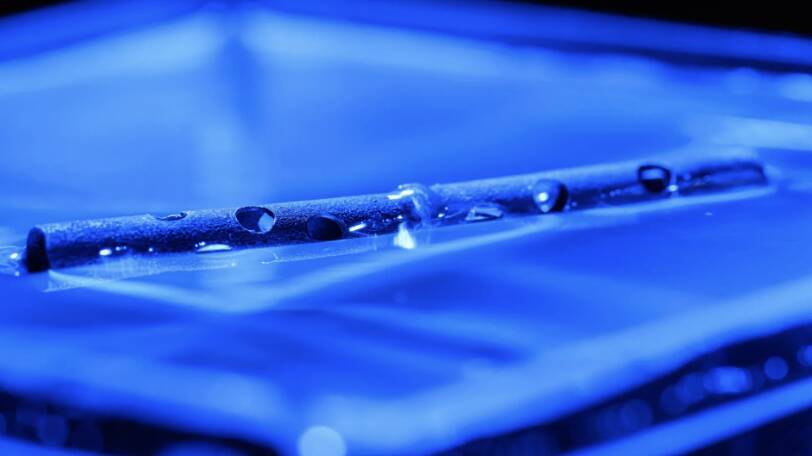

The key to this innovation lies in the creation of highly buoyant metal tube structures that can float even when submerged for long periods or damaged with holes. By processing aluminium in a unique way, the researchers were able to add nanometer-scale grooves to the surface of the metal tubes, making them superhydrophobic. This means that the tubes are able to repel water and maintain a stable layer of air bubbles on their inner surface, even when fully submerged.

The implications of this technology are enormous. If used to build ships, these metal tubes could provide a level of buoyancy and stability that would make it virtually impossible for the vessel to sink. Even if the ship were to suffer significant damage, such as a breach of the hull, the metal tubes would continue to provide lift and keep the vessel afloat.

The development of this technology is the result of a deep understanding of the properties of materials at the nanoscale. By manipulating the surface structure of the aluminium tubes, the researchers were able to create a material that is not only superhydrophobic but also extremely durable. The nanometer-scale grooves on the surface of the tubes create a layer of air that is trapped between the metal and the surrounding water, reducing the drag on the material and allowing it to float more easily.

One of the most significant advantages of this technology is its potential to improve safety at sea. Every year, countless lives are lost in maritime accidents, often as a result of ships sinking or capsizing. The use of unsinkable metal tubes could dramatically reduce the risk of such accidents, providing a level of protection for crew and passengers that is currently unavailable.

In addition to its potential to improve safety, this technology could also have a major impact on the maritime industry as a whole. The ability to build ships that are virtually unsinkable could revolutionize the way that goods are transported across the world’s oceans. With the risk of sinking or damage significantly reduced, shipping companies could operate with greater confidence and efficiency, reducing costs and increasing productivity.

The potential applications of this technology extend far beyond the maritime industry, however. The use of superhydrophobic materials could have a major impact on a wide range of fields, from aerospace to biomedical engineering. For example, the development of superhydrophobic surfaces could be used to create more efficient and effective medical implants, or to improve the performance of aircraft and spacecraft.

While the development of unsinkable metal tubes is a major breakthrough, there are still many challenges to be overcome before this technology can be widely adopted. For example, the cost of producing these materials is currently relatively high, making them less competitive with traditional materials. Additionally, further research is needed to fully understand the properties and behavior of these materials in different environments and conditions.

Despite these challenges, the potential of this technology is undeniable. The development of unsinkable metal tubes has the potential to revolutionize the way that we build and operate ships, and could have a major impact on a wide range of industries and fields. As researchers continue to explore and develop this technology, we can expect to see significant advances in the years to come.

In conclusion, the development of metal tubes that could enable unsinkable ships is a major breakthrough that has the potential to transform the maritime industry and beyond. With its potential to improve safety, efficiency, and productivity, this technology is an exciting and promising development that is worth watching in the years to come.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm