Scientists develop metal tubes that could enable unsinkable ships

The concept of an “unsinkable ship” has long been a topic of fascination and debate among shipbuilders, engineers, and scientists. While the idea of a ship that can withstand any amount of damage and remain afloat may seem like the stuff of science fiction, recent breakthroughs in materials science may be bringing us closer to making this a reality. A team of scientists has developed a highly buoyant metal tube structure by processing aluminium, which can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to revolutionize the shipbuilding industry and could potentially be used to make “unsinkable ships”.

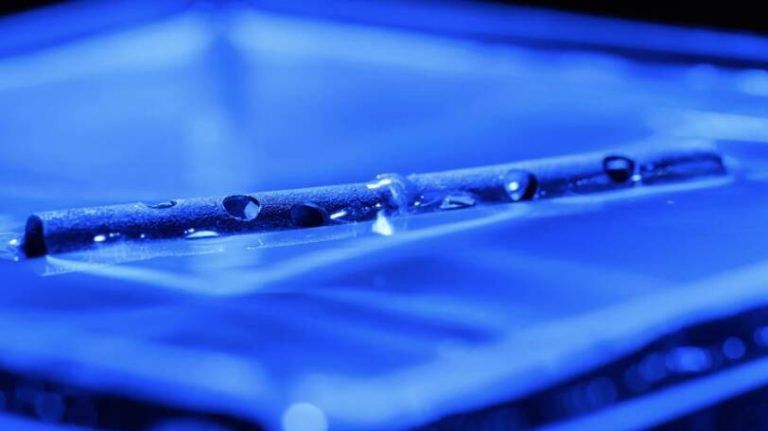

The secret to this new technology lies in the creation of nanometer-scale grooves on the surface of aluminium tubes. By adding these tiny grooves, the scientists were able to make the metal tubes superhydrophobic, meaning that they are extremely resistant to water. This property allows the tubes to stably maintain air bubbles on their inner surface, which in turn enables them to remain buoyant even when damaged or submerged for extended periods.

To create these superhydrophobic aluminium tubes, the scientists used a process called anodization, which involves passing an electric current through the metal in the presence of an acidic solution. This process creates a layer of tiny, nanometer-scale pores on the surface of the metal, which gives it its superhydrophobic properties. The researchers then used a technique called electrochemical etching to create the nanometer-scale grooves on the surface of the tubes.

The resulting metal tubes are not only highly buoyant but also incredibly durable. In tests, the tubes were able to withstand significant damage, including holes and dents, without losing their buoyancy. This is because the superhydrophobic surface of the tubes allows them to maintain a layer of air bubbles on their inner surface, which provides additional buoyancy and helps to keep them afloat.

The potential applications of this technology are vast and varied. One of the most exciting possibilities is the development of “unsinkable ships” that can withstand even the most extreme conditions at sea. Imagine a ship that can survive a catastrophic event, such as a collision or a storm, and remain afloat long enough for passengers and crew to be rescued. This could potentially save countless lives and reduce the risk of maritime disasters.

In addition to its potential use in shipbuilding, this technology could also have applications in other fields, such as offshore oil and gas production, where buoyant structures are used to support drilling and production equipment. The superhydrophobic metal tubes could also be used to create more efficient and durable marine equipment, such as propellers and pumps.

The development of this technology is also an important step forward in the field of materials science. The creation of superhydrophobic surfaces has long been a topic of interest among scientists, who have been working to develop new materials and techniques that can mimic the properties of natural surfaces, such as the lotus leaf. The development of these nanometer-scale grooves on the surface of aluminium tubes is a significant breakthrough in this field and could have far-reaching implications for a wide range of industries.

In conclusion, the development of highly buoyant metal tubes by processing aluminium is a significant breakthrough that could potentially be used to make “unsinkable ships”. The creation of superhydrophobic surfaces with nanometer-scale grooves has enabled the development of metal tubes that can float even when submerged for long periods or damaged with holes. This technology has the potential to revolutionize the shipbuilding industry and could have far-reaching implications for a wide range of fields, from offshore oil and gas production to marine equipment manufacturing. As scientists continue to develop and refine this technology, we may soon see the development of ships that are truly unsinkable.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm