Scientists develop metal tubes that could enable unsinkable ships

The concept of unsinkable ships has long been a topic of interest and debate in the maritime industry. While we’ve made significant advancements in shipbuilding technology, the risk of sinking still exists, especially in harsh weather conditions or in the event of damage. However, a recent breakthrough by scientists could potentially revolutionize the way we build ships. By developing highly buoyant metal tube structures, researchers have created a material that can float even when submerged for long periods or damaged with holes.

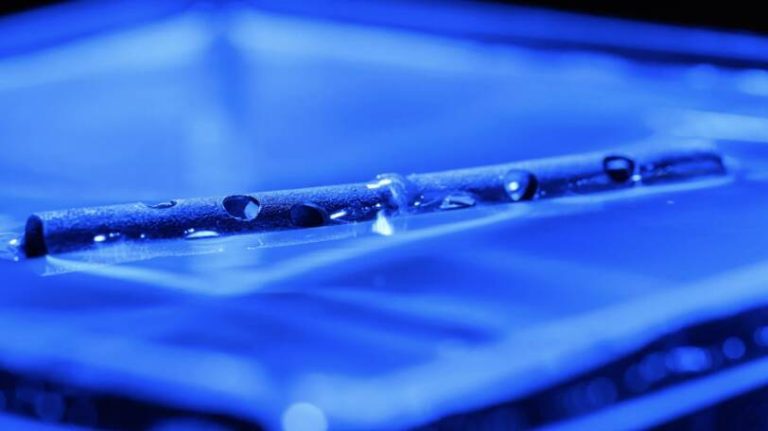

The innovative material is made from aluminium, a metal that is commonly used in shipbuilding due to its lightweight and corrosion-resistant properties. However, aluminium itself is not buoyant, and it would normally sink if submerged in water. To overcome this limitation, scientists added nanometer-scale grooves to the aluminium tubes, making them superhydrophobic. This means that the surface of the metal is extremely resistant to water, causing it to bead up and roll off easily.

The addition of nanometer-scale grooves to the aluminium tubes has a profound effect on their behavior in water. When submerged, the tubes are able to stably maintain air bubbles on their inner surface, which provides the necessary buoyancy to keep them afloat. This is a significant departure from traditional shipbuilding materials, which often rely on bulky and heavy buoyancy aids to stay afloat.

The potential applications of this technology are vast and exciting. For instance, unsinkable ships could be designed to withstand even the most extreme weather conditions, reducing the risk of accidents and improving safety at sea. Additionally, the use of buoyant metal tubes could enable the creation of more efficient and environmentally friendly ships, as they would require less energy to stay afloat and could potentially reduce their carbon footprint.

The development of unsinkable ships could also have a significant impact on various industries, including maritime transportation, offshore oil and gas, and naval defense. For example, unsinkable ships could be used to transport goods and supplies to remote or hard-to-reach areas, without the risk of sinking or damage. They could also be used to support offshore oil and gas operations, providing a safe and stable platform for drilling and production activities.

Furthermore, the use of buoyant metal tubes could enable the creation of new types of ships and vessels, such as floating cities or offshore platforms. These structures could provide a sustainable and self-sufficient way of living, with the potential to support large populations and reduce the strain on coastal cities and ecosystems.

While the development of unsinkable ships is still in its early stages, the potential benefits are clear. By providing a safe, efficient, and environmentally friendly way of building ships, this technology could revolutionize the maritime industry and have a significant impact on various aspects of our lives.

In conclusion, the development of highly buoyant metal tube structures by scientists is a groundbreaking achievement that could enable the creation of unsinkable ships. By adding nanometer-scale grooves to aluminium tubes, researchers have created a material that can float even when submerged for long periods or damaged with holes. This technology has the potential to transform the maritime industry, improve safety at sea, and reduce the environmental impact of shipping. As we continue to explore the possibilities of this innovation, it’s exciting to think about the potential applications and benefits that it could bring.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm