Scientists develop metal tubes that could enable unsinkable ships

The concept of an “unsinkable ship” has long been a topic of fascination and debate in the maritime industry. While some ships have been designed with advanced safety features to prevent sinking, there has never been a foolproof way to guarantee that a ship will remain afloat, even in the most treacherous of conditions. However, a recent breakthrough in materials science may be about to change that. Scientists have developed a highly buoyant metal tube structure by processing aluminium that can float even when submerged for long periods or damaged with holes.

This innovative technology has the potential to revolutionize the shipping industry, enabling the creation of “unsinkable ships” that could withstand even the most extreme conditions. The development of such ships could have a significant impact on maritime safety, reducing the risk of accidents and preventing the loss of life and cargo. But how does this technology work, and what are the potential implications for the shipping industry?

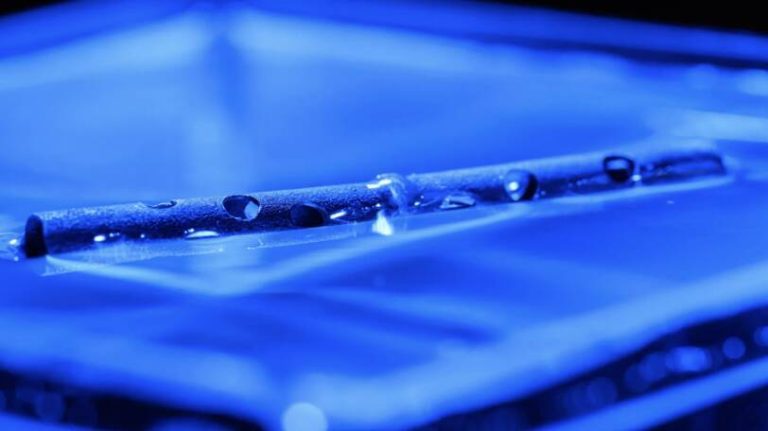

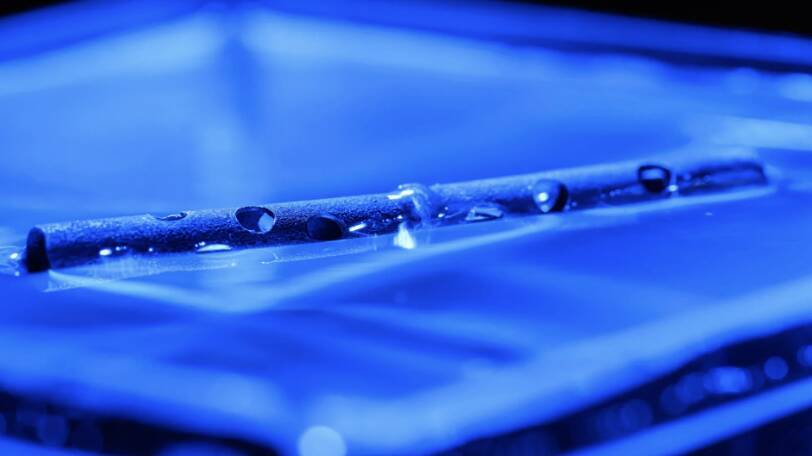

The key to this breakthrough lies in the processing of aluminium, a metal that is already known for its high strength-to-weight ratio and corrosion resistance. By adding nanometer-scale grooves to aluminium tubes, scientists have been able to create a superhydrophobic surface that is able to stably maintain air bubbles on the inner surface. This creates a highly buoyant structure that can float even when submerged in water.

The process of creating these metal tubes involves several stages. First, the aluminium tubes are treated with a specialized coating that creates the nanometer-scale grooves. This coating is designed to be extremely thin, measuring only a few nanometers in thickness. The grooves are then carefully controlled to create a specific pattern, which is designed to maximize the buoyancy of the tube.

Once the coating is applied, the tubes are then subjected to a series of tests to evaluate their buoyancy and durability. These tests involve submerging the tubes in water and observing their behavior over time. The results have been impressive, with the tubes showing a remarkable ability to maintain their buoyancy even when damaged with holes.

The implications of this technology are significant. If it is possible to create metal tubes that can float even when submerged or damaged, it may be possible to build ships that are virtually unsinkable. Such ships would be able to withstand even the most extreme conditions, including storms, collisions, and other hazards. This could have a major impact on maritime safety, reducing the risk of accidents and preventing the loss of life and cargo.

In addition to its potential applications in the shipping industry, this technology could also have implications for other fields, such as offshore oil and gas production, and coastal protection. For example, the use of buoyant metal tubes could provide a new way to protect coastal communities from the impact of storms and sea level rise.

While the development of unsinkable ships is still in its early stages, the potential benefits are clear. With further research and development, it may be possible to create ships that are not only safer but also more efficient and environmentally friendly. The use of buoyant metal tubes could reduce the need for ballast tanks, which are currently used to stabilize ships and prevent them from capsizing. This could lead to significant reductions in fuel consumption and greenhouse gas emissions.

In conclusion, the development of metal tubes that can float even when submerged or damaged is a significant breakthrough with major implications for the shipping industry. The potential to create unsinkable ships could revolutionize maritime safety, reducing the risk of accidents and preventing the loss of life and cargo. While further research and development are needed to fully realize the potential of this technology, the future looks bright for this innovative new material.

Source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm