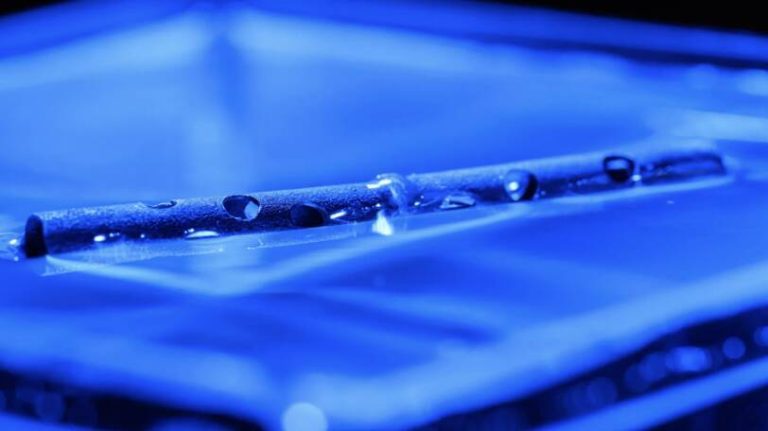

Scientists develop metal tubes that could enable unsinkable ships

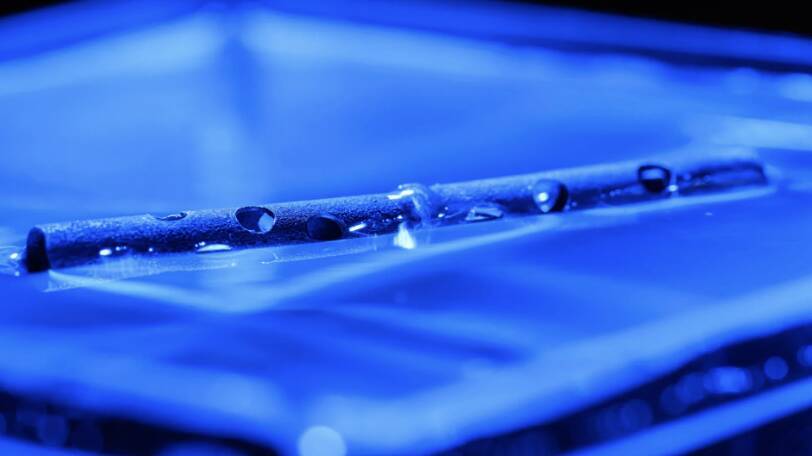

The concept of unsinkable ships has long been a topic of interest in the maritime industry. While some ships are designed to be more buoyant than others, the possibility of a ship sinking due to damage or other factors is always a concern. However, a recent breakthrough in materials science may change this narrative. Scientists have developed a highly buoyant metal tube structure by processing aluminium that can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to revolutionize the shipbuilding industry and make unsinkable ships a reality.

The secret to this breakthrough lies in the unique properties of the metal tubes. By adding nanometer-scale grooves to aluminium tubes, the scientists were able to make them superhydrophobic, meaning they repel water. This property allows the tubes to stably maintain air bubbles on the inner surface, which provides the necessary buoyancy to keep the structure afloat. The researchers achieved this by using a technique called anodization, which involves passing an electric current through the aluminium tubes to create the nanometer-scale grooves.

The results of this research are impressive. The metal tubes were able to float in water even when submerged for extended periods, and they remained buoyant even after being damaged with holes. This is a significant improvement over traditional materials used in shipbuilding, which can become waterlogged and lose their buoyancy when damaged. The potential applications of this technology are vast, ranging from the development of unsinkable ships to the creation of more efficient and stable offshore platforms.

One of the most significant advantages of this technology is its ability to provide a high level of safety in emergency situations. In the event of a ship sinking, the metal tubes could help to keep the vessel afloat, giving passengers and crew more time to evacuate. This could potentially save lives and reduce the risk of injury or death. Additionally, the use of these metal tubes could reduce the environmental impact of shipwrecks, as they would be less likely to release oil or other hazardous materials into the water.

The development of unsinkable ships could also have significant economic benefits. Shipowners and operators could save millions of dollars in repair and maintenance costs, as the metal tubes would be more resistant to damage and corrosion. Additionally, the increased safety and reliability of these ships could lead to lower insurance premiums and reduced liability costs.

While the development of unsinkable ships is still in its infancy, the potential benefits of this technology are clear. The use of superhydrophobic metal tubes could revolutionize the shipbuilding industry and make maritime transportation safer, more efficient, and more environmentally friendly. As researchers continue to develop and refine this technology, we can expect to see significant advancements in the coming years.

In conclusion, the development of metal tubes that can enable unsinkable ships is a groundbreaking achievement that has the potential to transform the maritime industry. The unique properties of these tubes, including their superhydrophobicity and ability to maintain air bubbles, make them an ideal material for shipbuilding. As this technology continues to evolve, we can expect to see significant improvements in safety, efficiency, and environmental sustainability. Whether you’re a shipowner, operator, or simply someone who is interested in the latest developments in materials science, this breakthrough is definitely worth keeping an eye on.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm