Scientists develop metal tubes that could enable unsinkable ships

The concept of an “unsinkable ship” has long been a topic of fascination and debate in the maritime industry. While there have been numerous attempts to create vessels that can withstand even the most catastrophic of events, none have been entirely successful. However, a recent breakthrough by a team of scientists may have brought us one step closer to realizing this dream. By developing a highly buoyant metal tube structure, researchers have created a material that can float even when submerged for long periods or damaged with holes.

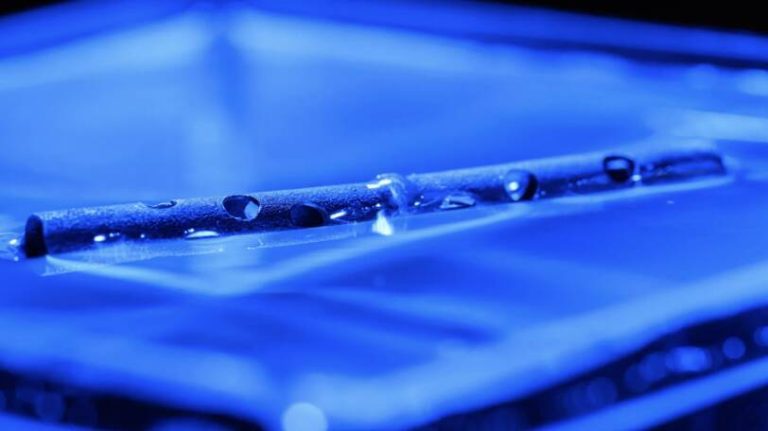

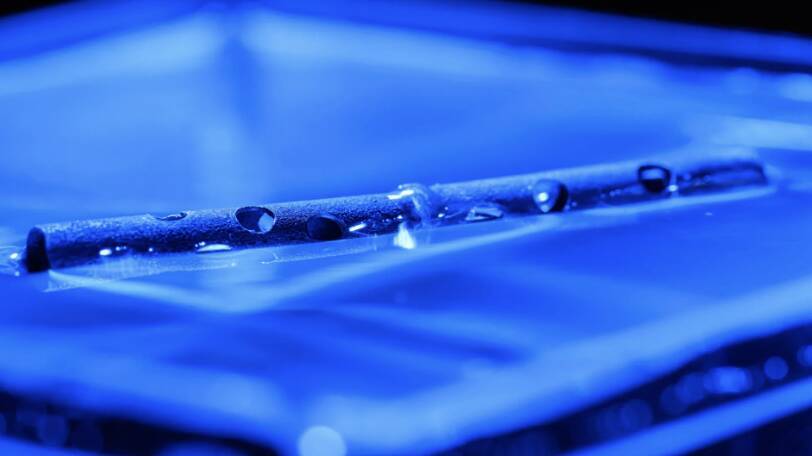

The key to this innovative technology lies in the processing of aluminium, a metal that is commonly used in shipbuilding due to its high strength-to-weight ratio. By adding nanometer-scale grooves to aluminium tubes, the scientists were able to create a superhydrophobic surface that is able to stably maintain air bubbles on the inner surface. This unique property allows the metal tubes to remain buoyant, even when submerged in water for extended periods.

The process of creating these superhydrophobic aluminium tubes involves a complex series of steps. First, the aluminium is subjected to a series of chemical treatments that create a layer of nano-scale grooves on the surface of the metal. These grooves are incredibly small, measuring only a few nanometers in depth and width. The treated aluminium is then formed into tubes, which are designed to be used as the primary structural component of a ship’s hull.

When submerged in water, the superhydrophobic surface of the aluminium tubes causes water to bead up and roll off, rather than penetrating the metal. This creates a layer of air bubbles on the inner surface of the tubes, which provides the buoyancy needed to keep the ship afloat. Even when the tubes are damaged with holes, the air bubbles are able to stabilize and maintain the buoyancy of the metal, allowing the ship to remain afloat.

The potential applications of this technology are vast and varied. The most obvious use is in the construction of “unsinkable ships” that can withstand even the most catastrophic of events. This could include naval vessels, cargo ships, and even passenger liners. The use of superhydrophobic aluminium tubes could also have significant implications for the offshore oil and gas industry, where the risk of accidents and spills is always a concern.

In addition to its potential use in shipbuilding, this technology could also be applied to other areas, such as aerospace and automotive engineering. The ability to create superhydrophobic surfaces on metals could have significant implications for the development of more efficient and durable materials.

While the development of superhydrophobic aluminium tubes is a significant breakthrough, there are still many challenges that must be overcome before this technology can be widely adopted. One of the primary concerns is the cost and complexity of the manufacturing process, which could make it difficult to scale up production to meet the demands of the maritime industry.

Another challenge is the need for further testing and validation of the technology. While the initial results are promising, more research is needed to fully understand the properties and behavior of superhydrophobic aluminium tubes in different environments and conditions.

Despite these challenges, the development of superhydrophobic aluminium tubes is an exciting and promising breakthrough that could have significant implications for the maritime industry. As researchers continue to refine and improve this technology, we may soon see the development of “unsinkable ships” that can withstand even the most catastrophic of events.

In conclusion, the development of metal tubes that can float even when submerged for long periods or damaged with holes is a significant breakthrough that could have far-reaching implications for the maritime industry. By creating a superhydrophobic surface on aluminium tubes, scientists have opened up new possibilities for the construction of “unsinkable ships” that can withstand even the most challenging conditions. As research and development continue to advance, we may soon see a new generation of ships that are safer, more efficient, and more durable than ever before.

News Source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm