Scientists develop metal tubes that could enable unsinkable ships

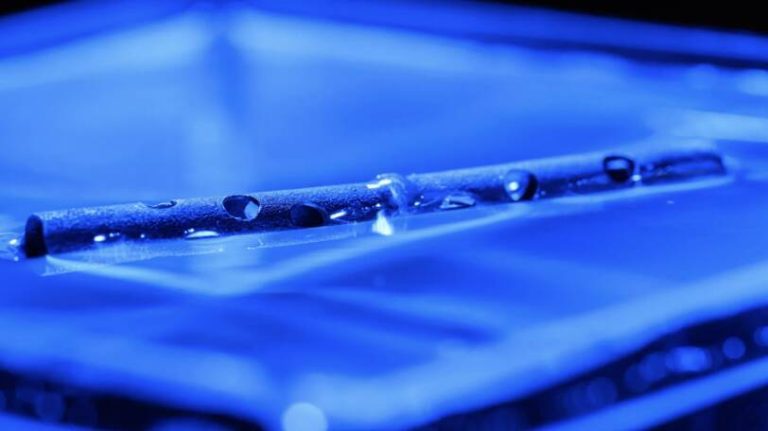

The concept of an unsinkable ship has long been a topic of interest and debate among scientists, engineers, and maritime experts. While we have made significant advancements in shipbuilding technology, the risk of sinking remains a major concern, particularly in harsh weather conditions or in the event of a catastrophic accident. However, a recent breakthrough in materials science may change this narrative forever. Scientists have developed a highly buoyant metal tube structure by processing aluminum that can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to revolutionize the shipbuilding industry and make “unsinkable ships” a reality.

The research team behind this breakthrough achieved this remarkable feat by adding nanometer-scale grooves to aluminum tubes, making them superhydrophobic. This unique property allows the tubes to stably maintain air bubbles on the inner surface, which provides the necessary buoyancy to keep the structure afloat. The scientists’ innovative approach involves creating a network of tiny grooves on the surface of the aluminum tubes, which are then treated with a specialized coating to enhance their water-repelling properties.

The resulting metal tube structure exhibits exceptional buoyancy, even when damaged or submerged in water for extended periods. The researchers conducted a series of experiments to test the limits of their creation, including drilling holes in the tubes and submerging them in water. To their surprise, the tubes continued to float, defying the conventional expectations of metal’s density and buoyancy. This remarkable property can be attributed to the superhydrophobic surface, which enables the tubes to maintain a layer of air bubbles on the inner surface, providing the necessary lift to keep the structure afloat.

The implications of this technology are vast and far-reaching. The development of unsinkable ships could revolutionize the maritime industry, enabling the creation of vessels that can withstand even the most extreme weather conditions. This could lead to significant improvements in safety, reducing the risk of accidents and fatalities at sea. Furthermore, the technology could also enable the creation of floating structures, such as offshore platforms, that can withstand harsh weather conditions and provide a stable base for operations.

The potential applications of this technology extend beyond the maritime industry. The superhydrophobic metal tubes could be used in a variety of fields, including aerospace, construction, and even biomedical engineering. For instance, the tubes could be used to create lightweight, buoyant structures for aircraft or spacecraft, or as a component in advanced medical devices, such as implantable sensors or surgical instruments.

While the development of unsinkable ships is still in its infancy, the potential benefits are undeniable. The researchers’ innovative approach to materials science has opened up new avenues for exploration and discovery, and their work is sure to inspire further research and development in this field. As we continue to push the boundaries of what is possible with materials science, we may soon find ourselves on the cusp of a revolution in shipbuilding technology, one that could change the face of the maritime industry forever.

In conclusion, the development of metal tubes that can float even when damaged or submerged is a groundbreaking achievement that has the potential to enable the creation of unsinkable ships. The innovative approach of the research team, involving the creation of nanometer-scale grooves on aluminum tubes, has resulted in a superhydrophobic surface that can stably maintain air bubbles on the inner surface. As we look to the future, it is exciting to consider the potential applications of this technology, from the creation of unsinkable ships to the development of advanced materials for a variety of industries. With continued research and development, we may soon find ourselves on the threshold of a new era in materials science, one that could change the world forever.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm