Scientists develop metal tubes that could enable unsinkable ships

The concept of unsinkable ships has long been a topic of interest and debate in the maritime industry. While there have been numerous attempts to create vessels that can withstand extreme conditions and remain afloat even in the event of significant damage, a team of scientists has made a groundbreaking discovery that could revolutionize the field. By developing a highly buoyant metal tube structure, these researchers have created a material that can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to enable the creation of unsinkable ships, and its implications are vast and exciting.

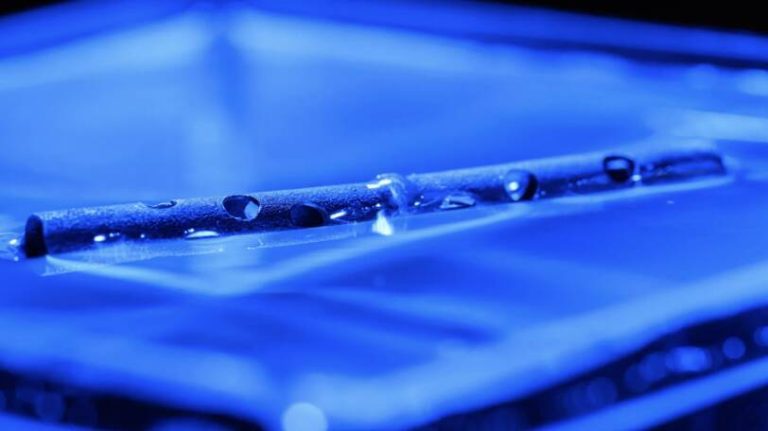

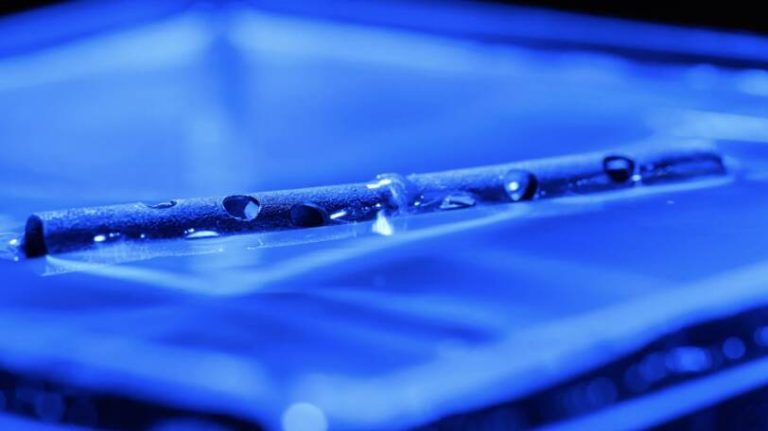

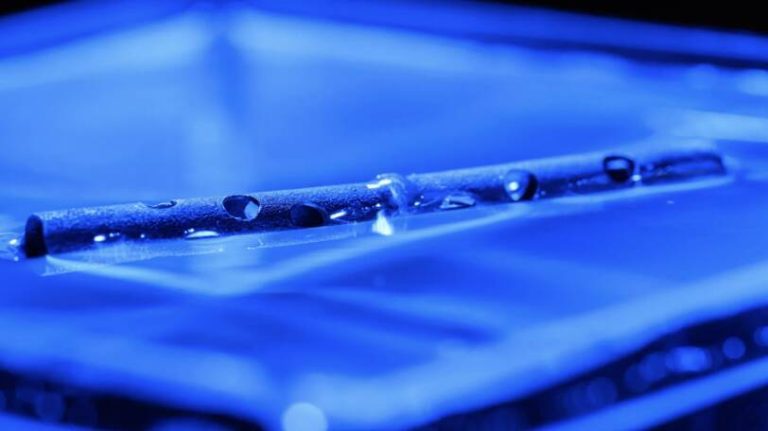

The key to this breakthrough lies in the processing of aluminium, a metal that is commonly used in shipbuilding due to its lightweight and corrosion-resistant properties. However, aluminium is not typically known for its buoyancy, which is essential for creating a structure that can remain afloat even when damaged. To overcome this limitation, the scientists added nanometer-scale grooves to aluminium tubes, making them superhydrophobic. This means that the surface of the metal is extremely resistant to water, allowing it to maintain a stable layer of air bubbles on its inner surface.

The addition of these nanometer-scale grooves is a crucial aspect of this technology. By creating a surface that is both hydrophobic and hydrophilic, the researchers were able to harness the power of surface tension to their advantage. When the aluminium tube is submerged in water, the air bubbles that form on its inner surface create a buoyant force that helps to keep the structure afloat. This effect is enhanced by the superhydrophobic properties of the metal, which allow it to repel water and maintain a stable layer of air bubbles even when damaged or submerged for extended periods.

The potential applications of this technology are vast and varied. In the maritime industry, the creation of unsinkable ships could revolutionize the way we design and build vessels. No longer would ships be at risk of sinking due to damage or flooding, which could save countless lives and prevent devastating environmental disasters. Additionally, this technology could be used to create more efficient and sustainable ships, as the reduced risk of sinking would allow for the use of lighter materials and more streamlined designs.

Beyond the maritime industry, this technology could have a significant impact on a wide range of fields. For example, it could be used to create more efficient and sustainable offshore platforms, such as oil rigs or wind farms. These structures are often at risk of damage or flooding due to extreme weather conditions, and the use of unsinkable materials could help to mitigate these risks. Additionally, this technology could be used to create more effective and sustainable solutions for coastal protection, such as sea walls or breakwaters.

The development of this technology is also a testament to the power of interdisciplinary research and collaboration. By combining expertise from materials science, mechanical engineering, and physics, the researchers were able to create a material that is both highly buoyant and incredibly durable. This collaborative approach is essential for driving innovation and solving complex problems, and it is likely to play a key role in the further development and refinement of this technology.

As with any new technology, there are likely to be challenges and limitations to the widespread adoption of unsinkable ships. For example, the cost and complexity of producing these materials may be prohibitively high, at least in the short term. Additionally, there may be regulatory or safety concerns that need to be addressed before this technology can be widely adopted. However, the potential benefits of this technology are so significant that it is likely to be worth pursuing, even if it requires significant investment and innovation.

In conclusion, the development of metal tubes that could enable unsinkable ships is a groundbreaking discovery that has the potential to revolutionize the maritime industry. By harnessing the power of surface tension and creating a material that is both highly buoyant and incredibly durable, the researchers have opened up new possibilities for the design and construction of ships and other offshore structures. As this technology continues to evolve and improve, it is likely to have a significant impact on a wide range of fields, from maritime engineering to coastal protection. With its potential to save lives, prevent environmental disasters, and create more efficient and sustainable solutions, this technology is an exciting and promising development that is worth watching in the years to come.

News Source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm