Scientists develop metal tubes that could enable unsinkable ships

The concept of unsinkable ships has long been a topic of fascination and debate among scientists, engineers, and maritime enthusiasts. While we have made significant advancements in shipbuilding technology, the risk of sinking remains a persistent concern, particularly in harsh weather conditions or in the event of damage. However, a recent breakthrough in materials science may revolutionize the way we build ships, making them virtually unsinkable. Scientists have developed a highly buoyant metal tube structure by processing aluminium, which can float even when submerged for long periods or damaged with holes.

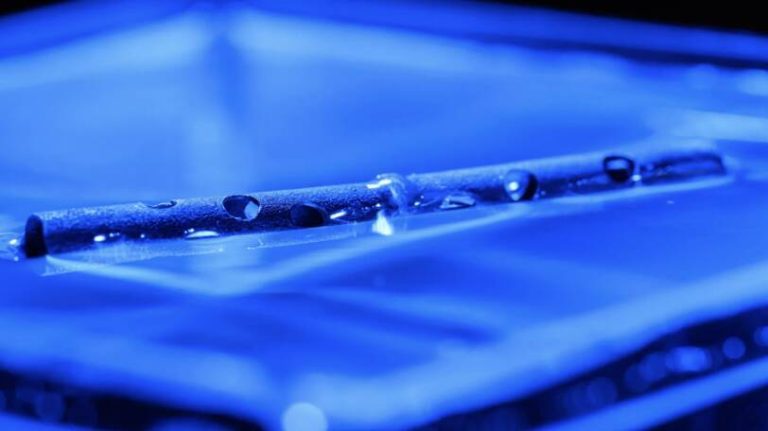

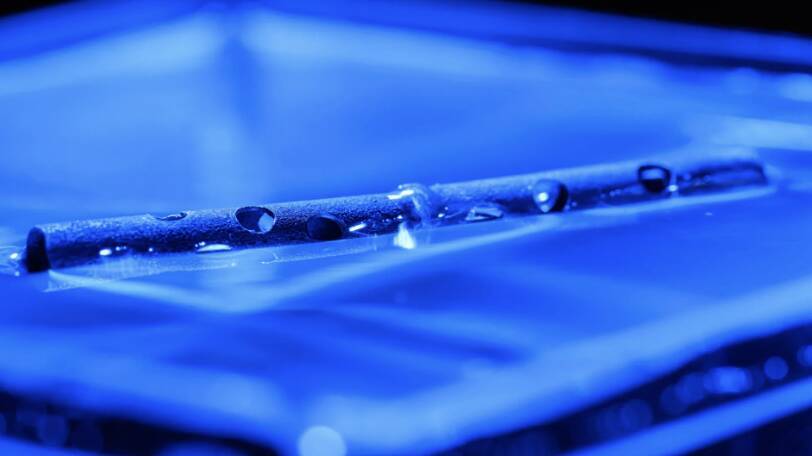

The innovative technology involves adding nanometer-scale grooves to aluminium tubes, making them superhydrophobic and able to stably maintain air bubbles on the inner surface. This unique property allows the metal tubes to remain afloat, even when subjected to extreme conditions. The potential applications of this technology are vast, and it could pave the way for the development of unsinkable ships that can withstand even the most challenging maritime environments.

To understand the significance of this breakthrough, let’s delve into the science behind superhydrophobic materials. Superhydrophobicity refers to the ability of a surface to repel water, causing it to bead up and roll off easily. This property is commonly found in nature, such as on the leaves of the lotus plant or the feathers of waterbirds. By replicating this phenomenon on aluminium tubes, scientists have created a material that can maintain a layer of air bubbles on its surface, even when submerged in water.

The process of creating these superhydrophobic aluminium tubes involves a complex series of steps. First, the aluminium tubes are treated with a specialized coating that creates nanometer-scale grooves on the surface. These grooves are precisely engineered to create a unique texture that allows air bubbles to form and stabilize on the surface. The treated tubes are then subjected to a series of tests, including submersion in water and exposure to various environmental conditions, to evaluate their buoyancy and durability.

The results of these tests have been nothing short of remarkable. The superhydrophobic aluminium tubes have demonstrated an extraordinary ability to remain afloat, even when damaged with holes or submerged for extended periods. This is due to the stable layer of air bubbles that forms on the surface of the tubes, which provides a buoyant force that counteracts the weight of the surrounding water.

The potential applications of this technology are vast and varied. One of the most significant implications is the development of unsinkable ships that can withstand even the most extreme maritime conditions. Imagine a ship that can navigate through treacherous storms, withstand collisions or damage, and remain afloat, even when submerged in water. This could revolutionize the shipping industry, providing a new level of safety and security for passengers and cargo.

In addition to its potential applications in shipbuilding, this technology could also be used in a range of other fields, including offshore oil and gas platforms, marine renewable energy systems, and even aerospace engineering. The ability to create superhydrophobic surfaces that can maintain a stable layer of air bubbles could have a significant impact on the design and functionality of various systems and structures.

While this breakthrough is certainly exciting, it’s essential to note that there are still several challenges to overcome before this technology can be widely adopted. One of the primary concerns is the scalability of the process, as well as the durability and maintenance requirements of the superhydrophobic surfaces. Additionally, there may be regulatory and safety considerations that need to be addressed before unsinkable ships can become a reality.

In conclusion, the development of superhydrophobic aluminium tubes is a significant breakthrough that could have a profound impact on various industries, including shipbuilding, offshore oil and gas, and aerospace engineering. The potential for creating unsinkable ships that can withstand even the most extreme conditions is a tantalizing prospect, and one that could revolutionize the way we design and build maritime vessels. As researchers continue to refine and develop this technology, we can expect to see significant advancements in the years to come.

For more information on this breakthrough, please visit: https://www.sciencedaily.com/releases/2026/01/260130041105.htm