Scientists develop metal tubes that could enable unsinkable ships

The concept of an “unsinkable ship” has long been a topic of fascination and debate among naval architects, engineers, and scientists. While the idea of a ship that can withstand any amount of damage or flooding may seem like the stuff of science fiction, a recent breakthrough in materials science may bring us one step closer to making this a reality. A team of scientists has developed a highly buoyant metal tube structure by processing aluminium, which can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to revolutionize the shipping industry and could potentially be used to make “unsinkable ships.”

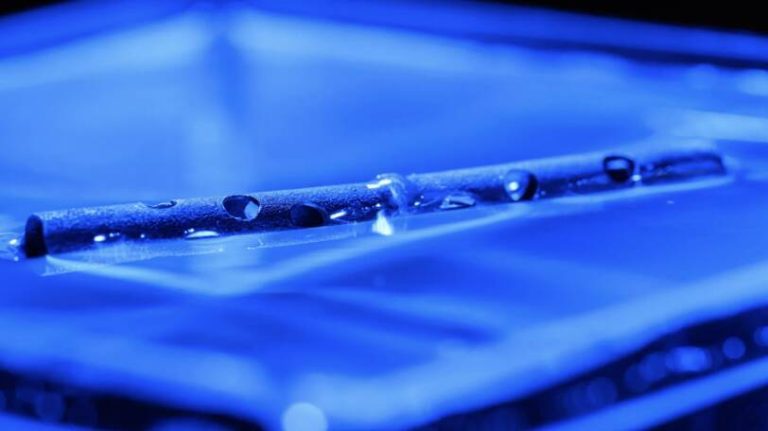

The key to this breakthrough lies in the development of a new type of metal tube that is not only extremely lightweight but also highly buoyant. By adding nanometer-scale grooves to aluminium tubes, the researchers were able to create a surface that is superhydrophobic, or extremely water-repellent. This unique property allows the tubes to stably maintain air bubbles on their inner surface, even when submerged in water. As a result, the tubes are able to maintain their buoyancy, even when damaged or punctured with holes.

The implications of this technology are significant. Traditional shipbuilding materials, such as steel, are dense and heavy, which can make them prone to sinking if damaged or flooded. In contrast, the new metal tubes developed by the scientists are not only lightweight but also highly buoyant, making them ideal for use in shipbuilding. By incorporating these tubes into the design of a ship, it may be possible to create a vessel that is virtually unsinkable, even in the event of catastrophic damage.

The potential benefits of this technology are numerous. For one, it could significantly improve the safety of ships and their crews. By reducing the risk of sinking, ships would be better equipped to withstand the harsh conditions of the open sea, and the risk of accidents and fatalities would be greatly reduced. Additionally, the use of highly buoyant metal tubes could also lead to the development of more efficient and sustainable ships, as they would require less energy to stay afloat and could potentially reduce their environmental impact.

The development of this technology is also a testament to the power of interdisciplinary research and collaboration. The team of scientists behind this breakthrough comes from a variety of backgrounds, including materials science, mechanical engineering, and naval architecture. By combining their expertise and knowledge, they were able to develop a truly innovative solution to a complex problem.

While the idea of an “unsinkable ship” may still seem like the stuff of science fiction, the development of these highly buoyant metal tubes brings us one step closer to making this a reality. As researchers continue to refine and develop this technology, it will be exciting to see the potential applications and implications that emerge.

In conclusion, the development of metal tubes that can float even when submerged for long periods or damaged with holes is a significant breakthrough with the potential to revolutionize the shipping industry. By creating a surface that is superhydrophobic and able to stably maintain air bubbles on the inner surface, the researchers have developed a highly buoyant material that could be used to make “unsinkable ships.” As this technology continues to evolve and develop, it will be exciting to see the potential benefits and applications that emerge.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm