Safer method boosts gas capture for clean energy

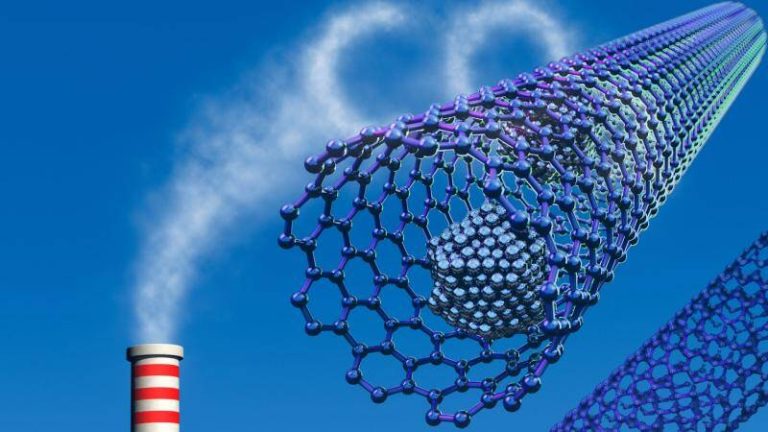

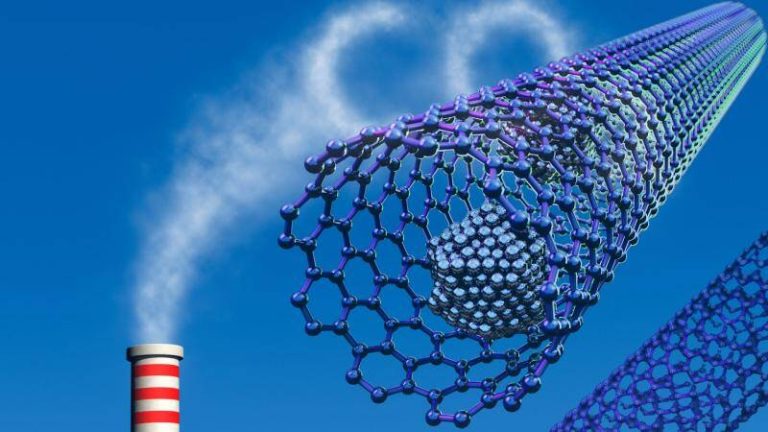

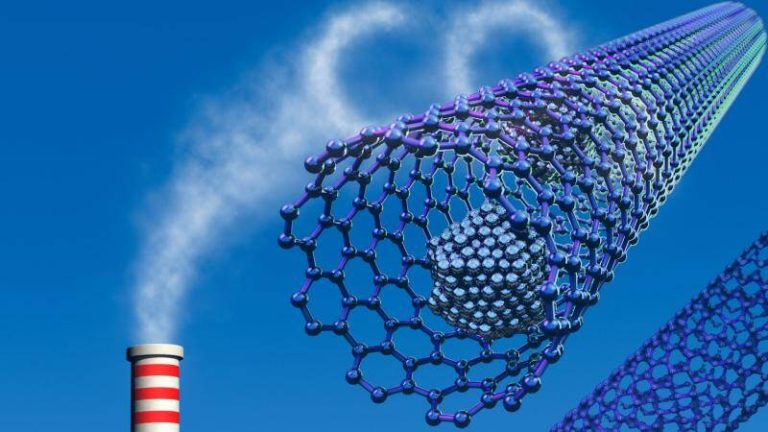

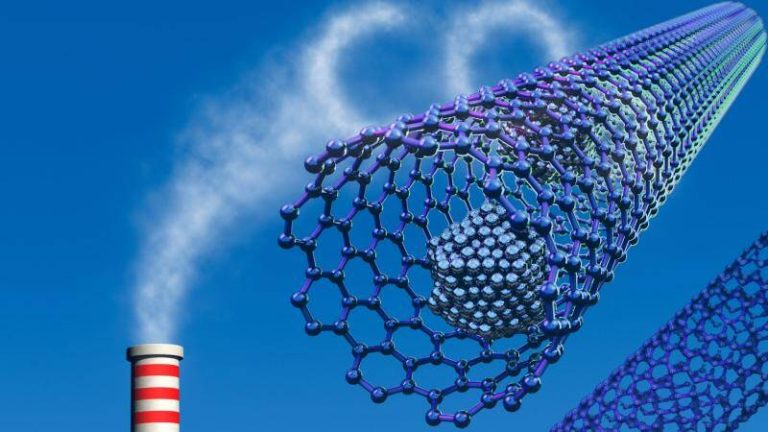

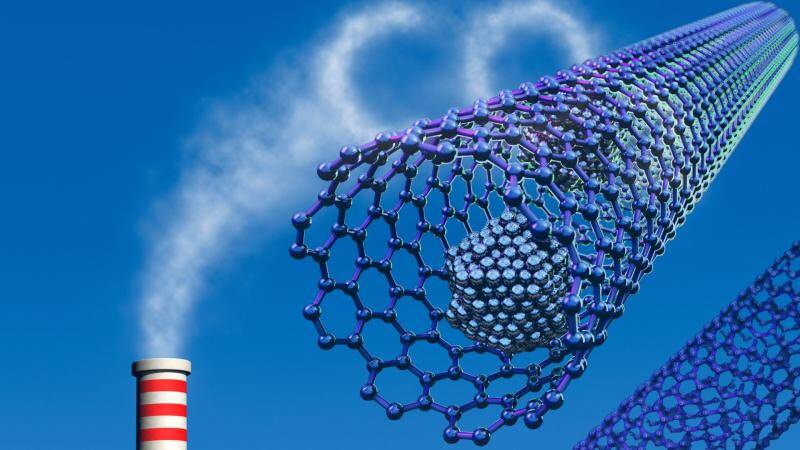

The world is grappling with the challenges of climate change, and one of the most effective ways to combat it is by reducing greenhouse gas emissions. Carbon capture and storage (CCS) is a crucial technology that can help mitigate the effects of climate change by capturing carbon dioxide (CO2) emissions from power plants and other industrial sources. However, the current methods of CCS are often expensive, energy-intensive, and rely on toxic chemicals. Recently, a team of researchers has developed a safer and more efficient method for synthesizing metal-organic frameworks (MOFs), which are porous materials that can trap greenhouse gases and store hydrogen.

The new method replaces toxic hydrofluoric acid (HF) with safer modulators, making it a more environmentally friendly and cost-effective way to produce MOFs. HF is a highly corrosive and toxic substance that requires special handling and equipment, which adds to the cost and complexity of the synthesis process. The researchers’ innovative approach uses fluoride-free synthesis, which not only eliminates the need for HF but also produces superior crystals that are more efficient at trapping gases.

MOFs are a class of materials that are composed of metal ions and organic linkers, which form a three-dimensional framework with a high surface area. This unique structure allows MOFs to adsorb and store gases, such as CO2, methane, and hydrogen, making them ideal for CCS applications. The new synthesis method produces MOFs with improved crystallinity, stability, and gas adsorption capacity, which can be used to develop more efficient carbon scrubbers and advanced atmospheric water harvesting systems.

The simplified method also enables the production of MOFs at room temperature, which reduces the energy requirements and makes the process more scalable. This is a significant advantage over traditional methods, which often require high temperatures and pressures to synthesize MOFs. The researchers’ approach also allows for greater control over the synthesis process, which enables the production of MOFs with specific properties tailored to specific applications.

The potential applications of this breakthrough are vast and varied. For example, the MOFs produced using this method could be used to develop more efficient carbon capture systems for power plants, industrial processes, and even vehicles. This could help reduce greenhouse gas emissions and mitigate the effects of climate change. Additionally, the MOFs could be used to store hydrogen, which is a clean-burning fuel that can be used to power vehicles and generate electricity.

The new synthesis method could also be used to develop advanced atmospheric water harvesting systems, which can extract water from air, even in arid environments. This technology has the potential to provide clean drinking water for millions of people around the world, particularly in areas where access to clean water is limited.

The researchers’ innovative approach is a significant step forward in the development of more efficient and sustainable CCS technologies. The use of safer modulators and fluoride-free synthesis reduces the environmental impact of the synthesis process and makes it more cost-effective. The production of superior crystals with improved gas adsorption capacity also enhances the performance of MOFs in CCS applications.

In conclusion, the development of a safer and more efficient method for synthesizing MOFs is a major breakthrough in the field of CCS. The new synthesis method has the potential to revolutionize the way we capture and store greenhouse gases, and could play a significant role in the global effort to combat climate change. As the world continues to grapple with the challenges of climate change, innovative solutions like this one are crucial for reducing greenhouse gas emissions and creating a more sustainable future.