Plastic that Heals Itself and is Stronger than Steel Developed

Imagine a world where plastics can repair themselves, change shape at will, and withstand extreme temperatures. Sounds like science fiction, right? Well, researchers at Texas A&M and the University of Tulsa have made this concept a reality with the development of a revolutionary new plastic called ATSP (Advanced Thermoplastic System). This game-changing material has the potential to transform industries and revolutionize the way we live and work.

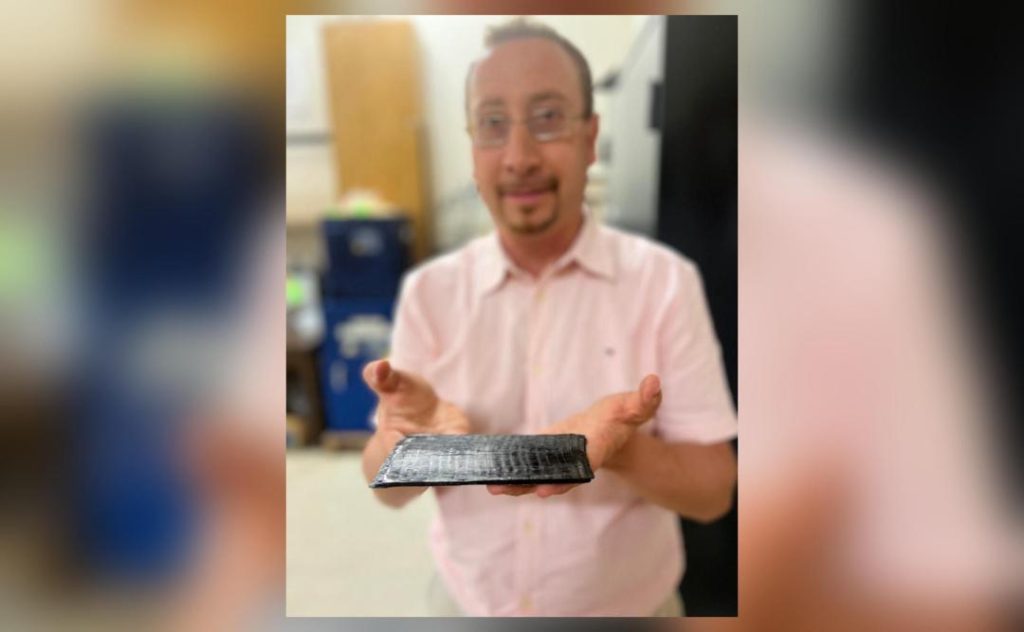

ATSP is a carbon-fiber-reinforced vitrimer, a type of plastic that exhibits unique properties that set it apart from traditional plastics. One of the most impressive features of ATSP is its ability to self-heal. Unlike traditional plastics that can crack or break when damaged, ATSP can repair itself by simply applying heat and pressure. This means that even if ATSP is scratched, dented, or cracked, it can regain its original strength and appearance.

But that’s not all – ATSP also has the ability to change shape under heat. This property, known as “shape-shifting,” allows ATSP to adapt to different environments and applications. Imagine a plastic that can adjust its shape to fit snugly around a specific object or surface, or one that can change shape to accommodate different temperatures or pressures.

Another remarkable feature of ATSP is its stability. Unlike traditional plastics that can degrade or lose their shape over time, ATSP remains stable through repeated use. This means that ATSP can withstand repeated heat cycles, exposure to chemicals, and other environmental stressors without losing its shape or functionality.

But what really sets ATSP apart is its strength. According to researchers, ATSP is stronger than steel, yet lighter than aluminum. This makes it an ideal material for a wide range of applications, from aerospace and defense to automotive and construction.

One of the most exciting aspects of ATSP is its recyclability. Unlike traditional plastics that are often difficult or impossible to recycle, ATSP can be melted down and reused multiple times without losing its strength or properties. This makes it an environmentally friendly option for industries that rely heavily on plastics.

So, what makes ATSP possible? According to researchers, the secret lies in its unique molecular structure. ATSP is made up of a special type of polymer that can reorganize its molecular bonds in response to heat and pressure. This allows it to self-heal, change shape, and regain its strength and properties.

But what are the potential applications of ATSP? The possibilities are endless. Imagine a world where plastics can be used in aerospace and defense applications, such as aircraft and spacecraft components, without worrying about damage or degradation. Imagine a world where plastics can be used in medical devices, such as implants and surgical instruments, that can adapt to different body temperatures and environments. Imagine a world where plastics can be used in construction and infrastructure, such as building materials and bridge components, that can withstand extreme temperatures and weather conditions.

The potential benefits of ATSP are vast and varied. Not only can it revolutionize industries and transform the way we live and work, but it can also help to reduce waste and improve sustainability. With its ability to self-heal, change shape, and regain its strength and properties, ATSP is the future of plastics.

As Dr. Michael R. Kessler, a materials science professor at Texas A&M, said in a statement, “ATSP has the potential to transform industries and revolutionize the way we use plastics. Its unique properties make it an ideal material for a wide range of applications, from aerospace and defense to automotive and construction.”

While ATSP is still in the early stages of development, it’s clear that this revolutionary new plastic has the potential to change the world. As researchers continue to refine and improve ATSP, we can expect to see a wide range of innovative applications and uses.

So, what do you think? Are you excited about the potential of ATSP? Do you have any ideas for how it could be used in different industries and applications? Share your thoughts and let’s explore the possibilities of this revolutionary new plastic.