Mohali Tech Institute Invents Water Filter to Purify Toxic Dyes

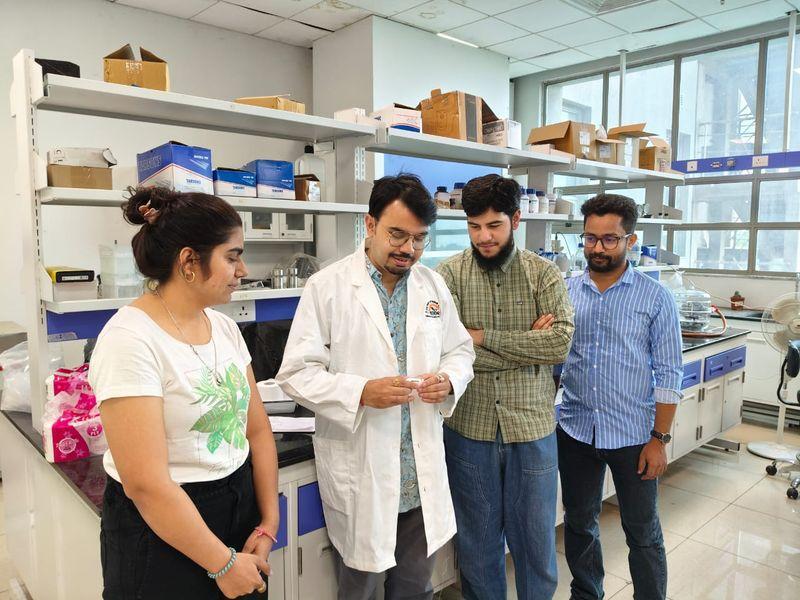

In a groundbreaking achievement, scientists at the Institute of Nano Science and Technology (INST), Mohali, Punjab, have developed a revolutionary water filter that can purify toxic dyes from industrial wastewater. This innovative technology is not only effective in removing pollutants from contaminated water but also breaks them down using a combination of sunlight and vibrations. The development has been hailed as a major breakthrough in eco-friendly water purification and has been featured as the cover art of the prestigious journal Nano Energy, published by Elsevier.

The filter, which is biodegradable and smart, uses a unique mechanism to remove toxic dyes from industrial wastewater. The process involves the use of nanomaterials that are sensitive to both sunlight and vibrations. When exposed to sunlight, the nanomaterials undergo a chemical reaction that breaks down the toxic dyes into harmless compounds. The vibrations, on the other hand, enhance the reaction process, allowing the filter to remove even the most stubborn pollutants.

The development of this water filter is a significant step towards solving one of the most pressing environmental issues of our time – the contamination of water bodies with toxic chemicals. Industrial wastewater, which is often discharged into rivers, lakes, and oceans without proper treatment, poses a serious threat to the health of aquatic life and human consumption.

The INST team, led by Dr. Suresh Kumar, a renowned expert in the field of nanomaterials and water purification, has been working on this project for several years. The scientists used a combination of experimental and theoretical approaches to develop the filter, which is designed to be cost-effective, easy to use, and environmentally friendly.

“We are thrilled to see our innovation featured as the cover art of Nano Energy,” said Dr. Kumar. “Our goal is to make a positive impact on the environment and public health, and we believe that our water filter has the potential to do just that.”

The filter has been tested on several types of industrial wastewater, including effluent from textile and dye manufacturing industries, and has been shown to be highly effective in removing toxic dyes. The technology has also been found to be scalable, making it suitable for use in a range of applications, from small-scale treatment plants to large industrial facilities.

The development of this water filter is not only a significant achievement for the INST team but also a testament to the power of interdisciplinary research. The project involved collaboration between experts in materials science, chemistry, and environmental engineering, highlighting the importance of cross-disciplinary approaches in addressing complex environmental challenges.

The impact of this innovation extends beyond the technical realm, as it has the potential to improve the lives of millions of people around the world who rely on contaminated water sources for their daily needs. The filter’s ability to break down toxic dyes also has implications for the textile and dye manufacturing industries, which are major polluters of water bodies.

In a world where pollution and environmental degradation are increasingly becoming major concerns, the development of this water filter is a beacon of hope. It shows that with innovative thinking, cutting-edge technology, and a commitment to environmental sustainability, we can overcome even the most daunting challenges.

As the world continues to grapple with the challenges of pollution and climate change, it is innovations like this water filter that give us hope for a better future. The INST team’s achievement is a reminder that even in the face of seemingly insurmountable challenges, human ingenuity and determination can achieve the impossible.