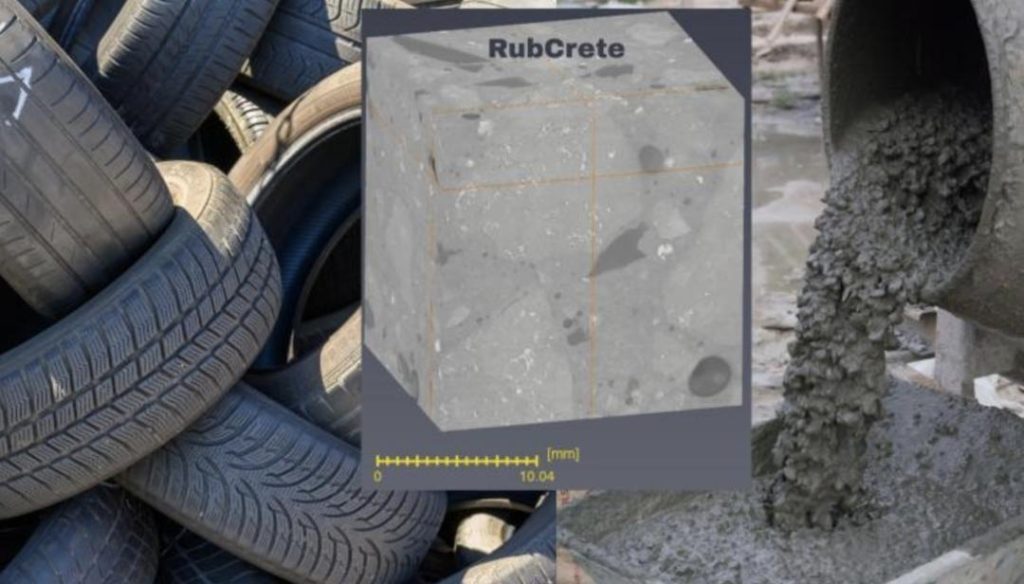

IIT Bombay’s RubCrete turns tyre waste into tough, green concrete

In a groundbreaking discovery, researchers at the Indian Institute of Technology (IIT) Bombay have successfully created a sustainable and eco-friendly concrete material called RubCrete, which is mixed with shredded rubber from waste tyres. This innovative material boasts unique properties that make it flexible and resistant to corrosive substances, making it an ideal solution for challenging environments. The research delves into the microscopic bond between the concrete and rubber, revealing a previously unknown porous zone that enables RubCrete to stand out from traditional concrete.

The Problem of Waste Tyres in India

India generates a staggering amount of waste tyres every year, with estimates suggesting that over 1.5 million tonnes of waste tyres are produced annually. This waste not only poses environmental concerns but also presents a significant economic burden on the country. Traditional methods of tyre disposal, such as burning or dumping, are neither environmentally friendly nor sustainable. Moreover, the disposal of waste tyres is often left to the municipalities, which can lead to a range of problems, including clogged drains, soil pollution, and the spread of diseases.

The Birth of RubCrete

In an effort to address the problem of waste tyres, researchers at IIT Bombay embarked on a mission to develop a sustainable and eco-friendly material that could utilize waste tyres. The team, led by Dr. Suresh Dasgupta, a professor at the Department of Civil Engineering, experimented with mixing shredded rubber with concrete. The result was RubCrete, a unique and innovative material that combines the strength of concrete with the flexibility of rubber.

Microscopic Bond: The Key to RubCrete’s Success

The researchers discovered that the key to RubCrete’s success lies in its microscopic bond between the concrete and rubber. When waste tyres are shredded and mixed with concrete, a unique porous zone is created. This porous zone, which is not present in traditional concrete, enables RubCrete to absorb and dissipate impact energy more effectively. As a result, RubCrete becomes more flexible and resistant to cracking, making it an ideal material for applications where concrete is typically weak, such as in areas with high foot traffic or extreme weather conditions.

Corrosion Resistance: A Surprising Advantage

One of the most significant advantages of RubCrete is its resistance to corrosive substances. Traditional concrete is prone to damage from acidic or alkaline substances, which can lead to cracking and degradation. RubCrete, on the other hand, is resistant to corrosion, making it an ideal material for applications where exposure to corrosive substances is likely.

Sustainable Material for Challenging Environments

RubCrete’s unique properties make it an ideal material for challenging environments, such as:

- High-traffic areas: RubCrete’s flexibility and resistance to cracking make it an excellent choice for areas with high foot traffic, such as airports, shopping malls, and public spaces.

- Extreme weather conditions: RubCrete’s resistance to corrosion and its ability to absorb and dissipate impact energy make it an ideal material for areas prone to extreme weather conditions, such as coastal regions or areas with high winds.

- Industrial applications: RubCrete’s resistance to corrosive substances makes it an excellent choice for industrial applications, such as manufacturing facilities, chemical plants, and oil refineries.

Reducing Waste, One Tyre at a Time

The development of RubCrete is a significant step towards reducing waste tyres and promoting sustainable development. By utilizing waste tyres in the production of RubCrete, India can reduce the environmental impact of tyre disposal and create a more circular economy.

Conclusion

IIT Bombay’s RubCrete is a groundbreaking innovation that has the potential to revolutionize the construction industry. By turning waste tyres into a tough and green concrete material, RubCrete offers a sustainable solution for challenging environments. As the world grapples with the problem of waste management, RubCrete is a shining example of how innovation can lead to a more eco-friendly and sustainable future.