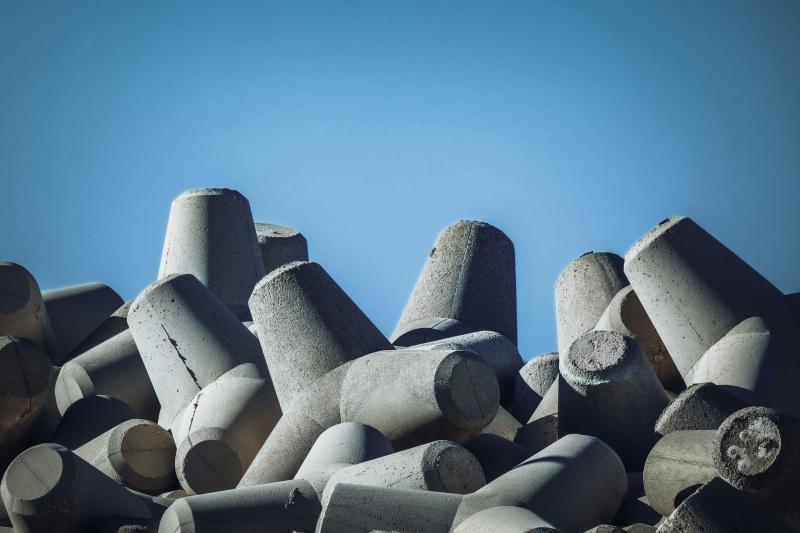

Marine Drive tetrapods inspire plastic research: Study

The Marine Drive in Mumbai is known for its beautiful promenade and stunning sea views. However, it’s not just the scenic beauty that’s caught the attention of researchers. The tetrapod-shaped wave breakers along the coastline have inspired a team of scientists from IIT Bombay, IIT Madras, and IIT Kanpur to explore their potential in improving plastic processing. In a recent study, the researchers discovered that nanoparticles shaped like tetrapods can reduce the viscosity of polymers, making it easier to process plastics.

The study, which was inspired by the unique shape of the wave breakers, suggests that tetrapod-shaped nanoparticles can create space for polymer chains to slide easily, reducing the viscosity of the polymer melt. This is in contrast to spherical nanoparticles, which tend to thicken fluids. The discovery has significant implications for the plastic processing industry, as it could lead to lower energy costs and improved efficiency.

To understand the significance of this study, let’s first delve into the world of polymers and their processing. Polymers are long chains of molecules that are used to create a wide range of materials, from plastics to fibers. The processing of polymers involves melting and shaping them into the desired form. However, this process can be energy-intensive, as it requires heating the polymer to high temperatures to reduce its viscosity.

The viscosity of a polymer is a measure of its resistance to flow. When a polymer is heated, its viscosity decreases, making it easier to process. However, adding spherical nanoparticles to the polymer can increase its viscosity, making it more difficult to process. This is because the spherical nanoparticles can get entangled with the polymer chains, creating a more rigid structure.

The researchers, however, found that tetrapod-shaped nanoparticles behave differently. The unique shape of these nanoparticles creates space for the polymer chains to slide easily, reducing the viscosity of the polymer melt. This is because the tetrapod shape allows the polymer chains to move freely, without getting entangled with the nanoparticles.

The study used computational simulations to model the behavior of tetrapod-shaped nanoparticles in polymer melts. The simulations showed that the tetrapod shape creates a “lubrication” effect, allowing the polymer chains to slide easily past each other. This reduces the viscosity of the polymer melt, making it easier to process.

The implications of this study are significant. The use of tetrapod-shaped nanoparticles could lead to lower energy costs in plastic processing, as it would require less heat to reduce the viscosity of the polymer. This could also lead to improved efficiency, as the polymer could be processed at lower temperatures.

The study also has implications for 3D printing applications. In 3D printing, the polymer is melted and deposited layer by layer to create the desired shape. The use of tetrapod-shaped nanoparticles could improve the flowability of the polymer, making it easier to create complex shapes.

The inspiration for this study came from the wave breakers along the Marine Drive in Mumbai. The tetrapod-shaped wave breakers are designed to reduce the force of the waves, creating a safer and more stable coastline. The researchers realized that the unique shape of these wave breakers could have applications in other fields, such as materials science.

The study is a great example of how nature can inspire innovation. The unique shape of the wave breakers has led to a breakthrough in plastic research, with significant implications for the industry. The use of tetrapod-shaped nanoparticles could lead to more efficient and cost-effective plastic processing, with benefits for both the environment and the economy.

In conclusion, the study on tetrapod-shaped nanoparticles is a significant breakthrough in plastic research. The unique shape of these nanoparticles creates space for polymer chains to slide easily, reducing the viscosity of the polymer melt. This discovery has implications for the plastic processing industry, with potential benefits for energy costs and efficiency. The study is also a great example of how nature can inspire innovation, with the tetrapod-shaped wave breakers along the Marine Drive in Mumbai providing the inspiration for this breakthrough.

Source: https://researchmatters.in/news/nanotetrapods-flowmakers-plastic-melts