What Drives Effective Supply Chain Models?

In today’s fast-paced and ever-changing business landscape, effective supply chain management is crucial for companies to stay ahead of the competition. A well-designed supply chain model can make all the difference in ensuring customer satisfaction, reducing costs, and increasing efficiency. But what drives an effective supply chain model? In this article, we’ll explore the key principles that successful brands use to balance flexibility and efficiency in their supply chain operations.

Network Alignment with Demand

One of the most critical aspects of an effective supply chain model is network alignment with demand. This means having a deep understanding of your customers’ needs and preferences, as well as being able to adapt to changes in the market. A supply chain that is aligned with demand can respond quickly to changes in consumer behavior, ensuring that products are delivered on time and in the right quantities.

To achieve this alignment, brands need to have a robust demand planning process in place. This involves analyzing historical sales data, market trends, and consumer behavior to forecast demand accurately. By having a clear understanding of what customers want, brands can optimize their production and inventory levels, reducing the risk of stockouts or overstocking.

Inventory Velocity

Inventory velocity is another key principle of effective supply chain models. This refers to the speed at which inventory moves through the supply chain, from raw materials to finished products. A supply chain with high inventory velocity is able to reduce lead times, increase responsiveness to customer demand, and improve cash flow.

There are several ways to improve inventory velocity, including implementing just-in-time (JIT) production and inventory management systems. These systems enable companies to produce and deliver products in small batches, reducing the need for inventory storage and minimizing the risk of inventory obsolescence.

Visibility Across Nodes

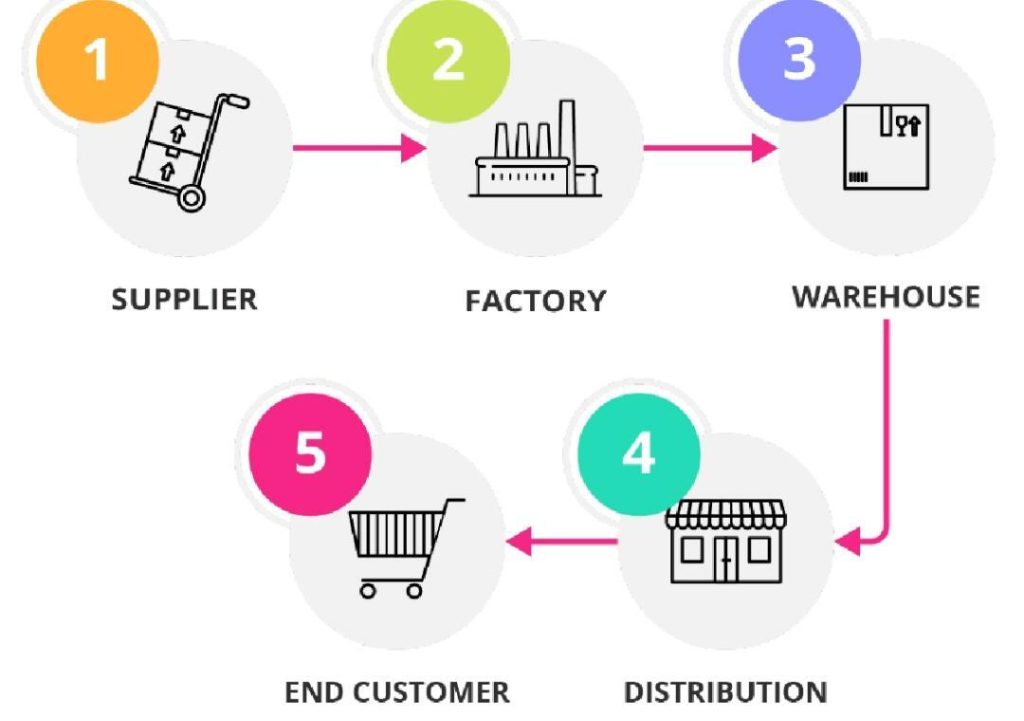

Visibility is critical in an effective supply chain model. This means having a clear understanding of what’s happening at every stage of the supply chain, from raw materials to customer delivery. By having visibility across nodes, brands can identify potential issues early on, reducing the risk of delays or stockouts.

There are several ways to achieve visibility across nodes, including implementing advanced logistics and transportation management systems. These systems enable companies to track inventory and shipments in real-time, providing valuable insights into supply chain performance.

Scenario Planning for Disruptions

Disruptions can occur at any stage of the supply chain, from natural disasters to supplier failures. To mitigate the impact of these disruptions, brands need to have a robust scenario planning process in place. This involves identifying potential risks and developing contingency plans to respond to them.

Scenario planning involves identifying potential disruptions, assessing the potential impact, and developing strategies to mitigate the risk. This can include identifying alternative suppliers, developing backup plans for production and inventory management, and having contingency plans in place for emergency situations.

Robustness and Adaptability

When it comes to supply chain management, robustness and adaptability are key. A robust supply chain is able to withstand disruptions and continue to operate effectively, while an adaptable supply chain is able to respond quickly to changes in the market.

To achieve robustness and adaptability, brands need to have a combination of both robust and agile supply chain systems in place. This can include implementing advanced logistics and transportation management systems, as well as having a flexible production and inventory management system.

Conclusion

In conclusion, effective supply chain models balance flexibility and efficiency. By having a deep understanding of customer demand, implementing inventory velocity strategies, achieving visibility across nodes, and developing scenario plans for disruptions, brands can ensure customer service continuity regardless of upstream challenges. When brands layer robustness with adaptability, they can respond quickly to changes in the market, reduce costs, and improve efficiency.

By following these principles, brands can create a supply chain model that is robust, adaptable, and customer-centric. This can help to drive business growth, improve customer satisfaction, and increase competitiveness in the market.

Source:

https://www.growthjockey.com/blogs/principles-supply-chain-operating-models