Scientists develop metal tubes that could enable unsinkable ships

The concept of unsinkable ships has long been a topic of fascination and debate in the maritime industry. While various materials and technologies have been explored to achieve this goal, a recent breakthrough by scientists may bring us closer to making this a reality. Researchers have successfully developed a highly buoyant metal tube structure by processing aluminium, which can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to revolutionize the shipbuilding industry and pave the way for the creation of unsinkable ships.

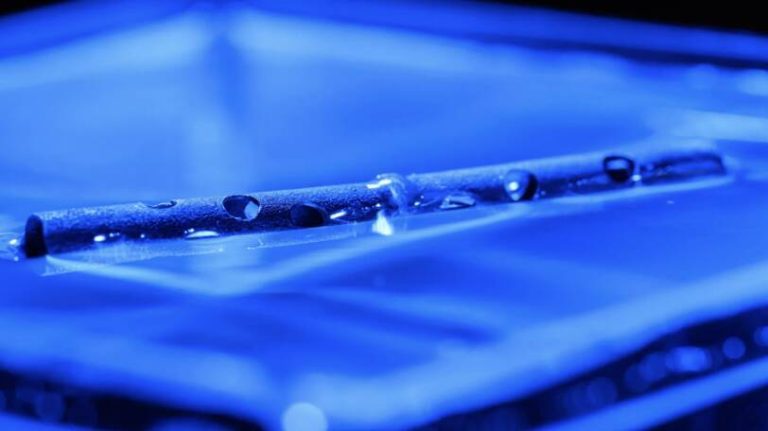

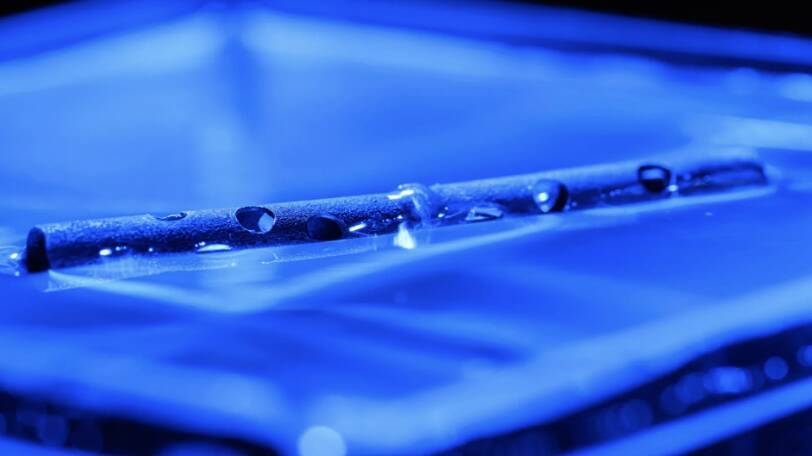

The key to this breakthrough lies in the processing of aluminium tubes, which were modified to have nanometer-scale grooves. These grooves make the metal tubes superhydrophobic, meaning they repel water, and enable them to stably maintain air bubbles on the inner surface. This unique property allows the metal tubes to remain buoyant, even when damaged or submerged for extended periods.

To achieve this, the scientists employed a technique called “anodization,” which involves passing an electric current through the aluminium tubes in an acidic solution. This process created a layer of tiny, nanometer-scale grooves on the surface of the tubes, giving them the superhydrophobic properties. The researchers then tested the modified aluminium tubes by submerging them in water and observing their behavior.

The results were impressive, with the metal tubes demonstrating exceptional buoyancy and stability. Even when damaged with holes, the tubes continued to float, thanks to the air bubbles trapped within the nanometer-scale grooves. This ability to maintain buoyancy, even in the face of damage, makes the metal tubes an attractive material for shipbuilding applications.

The potential implications of this technology are significant. If used in the construction of ships, these metal tubes could provide a level of safety and stability previously unimaginable. Ships made with these tubes could potentially withstand damage from collisions, groundings, or other accidents, and remain afloat, even in extreme conditions.

Moreover, this technology could also have applications beyond shipbuilding. For example, it could be used in the development of offshore platforms, buoys, or other marine structures that require high levels of buoyancy and stability. The superhydrophobic properties of the metal tubes could also be exploited in other fields, such as aerospace or biomedical engineering, where water-repellent materials are highly valued.

While this breakthrough is undoubtedly exciting, it is essential to note that significant challenges must be overcome before this technology can be widely adopted. For instance, the cost and complexity of producing the modified aluminium tubes on a large scale must be addressed. Additionally, the long-term durability and performance of the metal tubes in various environmental conditions must be thoroughly tested and validated.

Despite these challenges, the development of these metal tubes represents a significant step forward in the pursuit of unsinkable ships. As researchers continue to refine and improve this technology, we may soon see the emergence of a new generation of ships and marine structures that are safer, more stable, and more resilient than ever before.

In conclusion, the creation of metal tubes with exceptional buoyancy and stability is a groundbreaking achievement that could have far-reaching implications for the maritime industry. As scientists and engineers continue to explore and develop this technology, we may soon witness the dawn of a new era in shipbuilding, one that is characterized by unprecedented levels of safety, efficiency, and sustainability.

For more information on this innovative technology, please visit: https://www.sciencedaily.com/releases/2026/01/260130041105.htm

News Source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm