Scientists develop metal tubes that could enable unsinkable ships

The development of unsinkable ships has long been a topic of interest in the maritime industry, with many attempts made to create vessels that can withstand even the most extreme conditions. While some progress has been made in this area, a recent breakthrough by a team of scientists could potentially revolutionize the field. By creating a highly buoyant metal tube structure through the processing of aluminum, these researchers have opened up new possibilities for the development of ships that can remain afloat even in the most challenging situations.

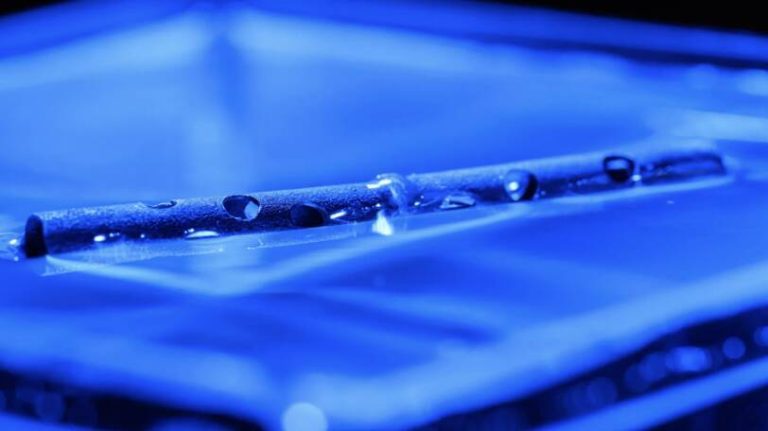

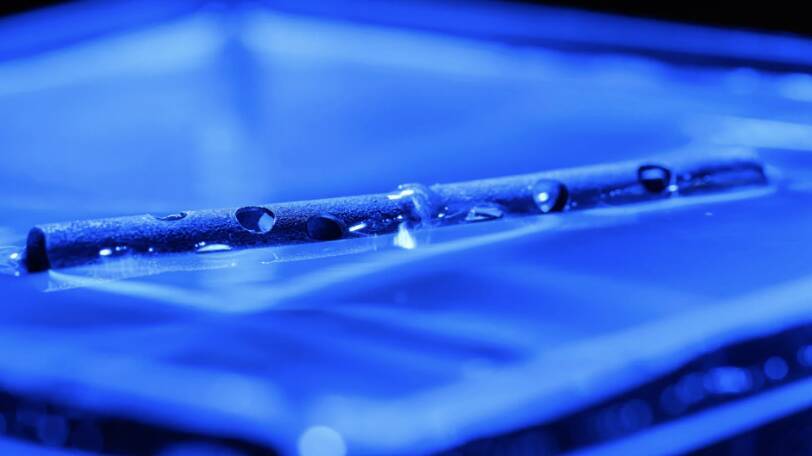

At the heart of this innovative technology is a unique approach to modifying the surface of aluminum tubes. By adding nanometer-scale grooves to the tubes, the scientists were able to create a superhydrophobic surface that is capable of stably maintaining air bubbles on the inner surface. This property, known as superhydrophobicity, is characterized by an extremely low affinity for water, allowing the tubes to repel water and maintain a layer of air next to the surface. As a result, the tubes are able to float even when submerged for extended periods or damaged with holes, making them ideal for use in the construction of unsinkable ships.

The potential applications of this technology are vast and varied, with the most obvious being the development of ships that can withstand even the most extreme conditions. Imagine a vessel that can survive a catastrophic breach or collision, remaining afloat even when damaged or submerged. Such a ship would be a game-changer in the maritime industry, providing a level of safety and security that is currently unimaginable.

But the potential uses of this technology extend far beyond the development of unsinkable ships. The highly buoyant metal tube structure could also be used in a variety of other applications, such as offshore oil and gas platforms, marine renewable energy systems, and even in the construction of floating cities. Anywhere that a high level of buoyancy and stability is required, this technology could potentially be used to provide a reliable and efficient solution.

One of the most significant advantages of this technology is its potential to improve safety at sea. Every year, countless lives are lost in maritime accidents, often due to the sinking of ships in extreme weather conditions or as a result of collisions or other damage. By developing ships that can withstand even the most challenging conditions, this technology could potentially save countless lives and prevent devastating accidents.

In addition to its potential to improve safety, this technology could also have a significant impact on the environment. By reducing the risk of ships sinking and releasing oil or other pollutants into the water, this technology could help to protect marine ecosystems and prevent devastating environmental disasters. Furthermore, the use of this technology in offshore oil and gas platforms could help to reduce the risk of spills and other accidents, providing a safer and more sustainable way to extract these vital resources.

The development of this technology is also a testament to the power of scientific innovation and collaboration. By bringing together experts from a variety of fields, including materials science, mechanical engineering, and physics, the researchers were able to develop a solution that is both elegant and effective. This collaborative approach is a model for future scientific research and development, demonstrating the potential for breakthroughs and innovations that can be achieved when experts work together to solve complex problems.

As this technology continues to develop and mature, it will be exciting to see the many potential applications that emerge. From unsinkable ships to offshore energy platforms, the possibilities are endless, and the potential benefits are vast. Whether used to improve safety, protect the environment, or simply to provide a more efficient and reliable way to conduct maritime operations, this technology is sure to have a significant impact on the world.

In conclusion, the development of highly buoyant metal tube structures through the processing of aluminum is a significant breakthrough with far-reaching potential. By creating a superhydrophobic surface that can stably maintain air bubbles on the inner surface, these researchers have opened up new possibilities for the development of unsinkable ships and other maritime applications. As this technology continues to evolve and improve, it will be exciting to see the many innovative solutions that emerge, and the potential benefits that they can bring to the maritime industry and beyond.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm