Scientists develop metal tubes that could enable unsinkable ships

The concept of unsinkable ships has long been a topic of interest and research in the field of naval architecture and engineering. While there have been significant advancements in ship design and materials, the risk of sinking remains a major concern, particularly in harsh marine environments. However, a recent breakthrough by scientists could potentially revolutionize the way ships are designed and constructed. By developing a highly buoyant metal tube structure, researchers have created a material that can float even when submerged for long periods or damaged with holes. This innovation has the potential to enable the creation of “unsinkable ships,” which could significantly improve safety and reduce the risk of maritime disasters.

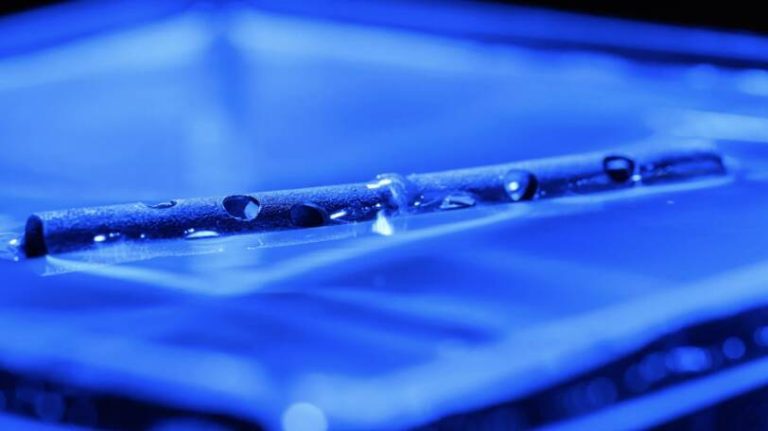

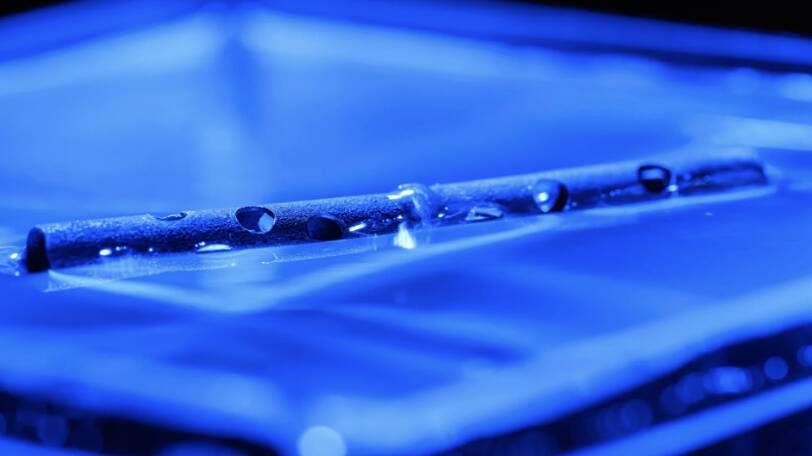

The key to this breakthrough lies in the processing of aluminium, a lightweight and versatile metal commonly used in shipbuilding. By adding nanometer-scale grooves to aluminium tubes, scientists were able to create a superhydrophobic surface that can stably maintain air bubbles on the inner surface. This unique property allows the metal tube to remain buoyant, even when submerged in water for extended periods. The researchers’ innovative approach has resulted in a material that is not only highly buoyant but also remarkably durable, with the ability to withstand significant damage without compromising its flotation capabilities.

The development of this technology is a significant step forward in the pursuit of creating unsinkable ships. Traditional shipbuilding materials, such as steel and fibreglass, can be dense and heavy, which can make them more susceptible to sinking in the event of damage. In contrast, the new metal tube structure is designed to provide exceptional buoyancy, even when damaged or submerged. This could potentially save lives and reduce the risk of maritime disasters, particularly in situations where ships are operating in harsh or unpredictable environments.

One of the most significant advantages of this technology is its potential to improve ship safety. In the event of a collision or other catastrophic event, the buoyant metal tube structure could help to keep the ship afloat, even if it suffers significant damage. This could provide valuable time for passengers and crew to evacuate the ship, reducing the risk of injury or loss of life. Additionally, the durable and long-lasting nature of the material could help to reduce maintenance costs and extend the lifespan of ships, making them more efficient and cost-effective to operate.

The potential applications of this technology extend beyond the development of unsinkable ships. The superhydrophobic surface of the metal tube structure could also be used in a variety of other industries, such as aerospace, automotive, and construction. For example, the material could be used to create lightweight and buoyant components for aircraft or spacecraft, or to develop advanced insulation materials for buildings. The possibilities are vast, and scientists are likely to explore a wide range of applications for this innovative material in the years to come.

While the development of unsinkable ships is still in its infancy, the potential benefits of this technology are undeniable. As researchers continue to refine and improve the metal tube structure, we can expect to see significant advancements in ship design and construction. The creation of unsinkable ships could revolutionize the maritime industry, providing a safer and more efficient way to transport people and goods across the globe.

In conclusion, the development of metal tubes that could enable unsinkable ships is a significant breakthrough in the field of naval architecture and engineering. By creating a highly buoyant and durable material, scientists have taken a major step forward in the pursuit of improving ship safety and reducing the risk of maritime disasters. As this technology continues to evolve, we can expect to see a wide range of applications across various industries, from aerospace to construction. The potential benefits are vast, and it will be exciting to see how this innovation shapes the future of shipbuilding and beyond.

Learn more about this breakthrough at: https://www.sciencedaily.com/releases/2026/01/260130041105.htm