Scientists develop metal tubes that could enable unsinkable ships

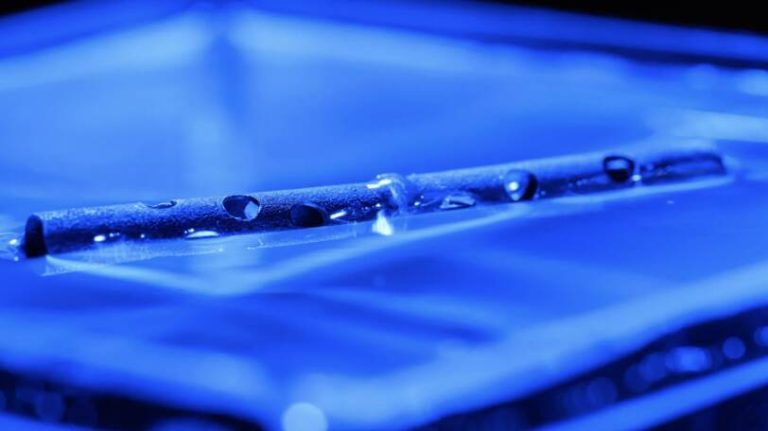

The concept of unsinkable ships has long been a topic of interest and debate in the maritime industry. While various technologies have been developed to improve the buoyancy and stability of ships, the idea of creating a truly unsinkable vessel has remained elusive. However, a recent breakthrough by scientists may bring us one step closer to achieving this goal. Researchers have developed a highly buoyant metal tube structure by processing aluminum, which can float even when submerged for long periods or damaged with holes.

The innovative technology involves adding nanometer-scale grooves to aluminum tubes, making them superhydrophobic and able to stably maintain air bubbles on the inner surface. This unique property allows the metal tubes to remain buoyant, even in the face of significant damage or water ingress. The implications of this discovery are profound, and it has the potential to revolutionize the design and construction of ships, boats, and other maritime vessels.

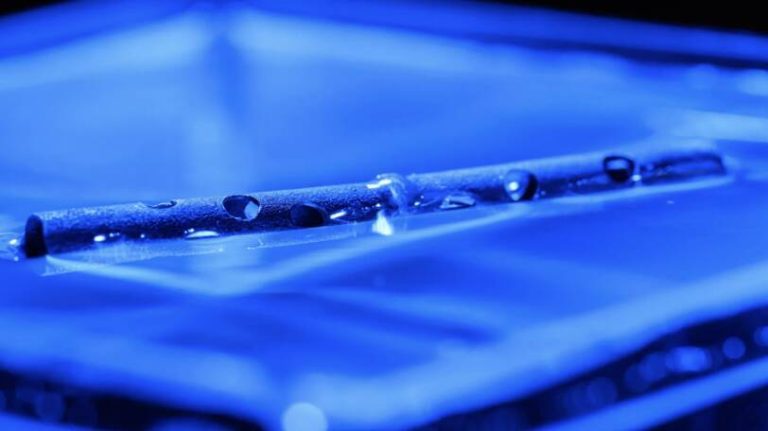

To understand the significance of this breakthrough, it’s essential to delve into the science behind it. The researchers used a process called “nanopatterning” to create the nanometer-scale grooves on the surface of the aluminum tubes. This process involves using advanced techniques such as lithography or etching to create tiny patterns on the metal surface. The resulting grooves are so small that they are measured in nanometers, which is one billionth of a meter.

The nanopatterning process creates a unique surface topography that gives the aluminum tubes their superhydrophobic properties. Superhydrophobicity refers to the ability of a surface to repel water, causing it to bead up and roll off easily. In the case of the aluminum tubes, the nanometer-scale grooves create a surface that is extremely difficult for water to penetrate. As a result, air bubbles can form and remain stable on the inner surface of the tubes, even when they are submerged in water.

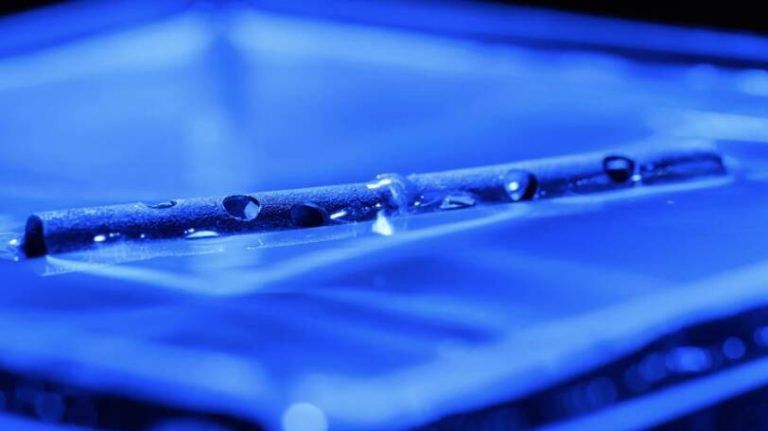

The ability of the metal tubes to maintain air bubbles on their inner surface is crucial to their buoyancy. When a ship or boat is damaged and takes on water, the air inside the vessel can become trapped, causing it to lose buoyancy and potentially sink. However, with the new metal tubes, the air bubbles on the inner surface can help to maintain the vessel’s buoyancy, even if it is damaged or flooded.

The potential applications of this technology are vast and varied. One of the most significant implications is the possibility of creating unsinkable ships. By using the buoyant metal tubes in the design and construction of vessels, shipbuilders could create ships that are highly resistant to sinking, even in the face of significant damage or flooding. This could revolutionize the maritime industry, particularly in areas such as offshore oil and gas exploration, where the risk of sinking is high.

Another potential application of this technology is in the development of more efficient and stable offshore platforms. These platforms are used for a variety of purposes, including oil and gas production, wind farms, and aquaculture. By using the buoyant metal tubes in the construction of these platforms, they could be made more stable and resistant to harsh weather conditions, reducing the risk of damage or collapse.

The technology could also have significant implications for the naval industry. Warships and submarines are often designed to operate in challenging environments, where the risk of damage or flooding is high. By incorporating the buoyant metal tubes into their design, these vessels could be made more resistant to sinking, even if they are damaged in combat or accidents.

In addition to these applications, the technology could also have significant implications for the development of more efficient and sustainable maritime vessels. By reducing the risk of sinking and improving the stability of ships, the buoyant metal tubes could help to reduce the environmental impact of the maritime industry. This could be particularly significant in areas such as cargo shipping, where the risk of accidents and oil spills is high.

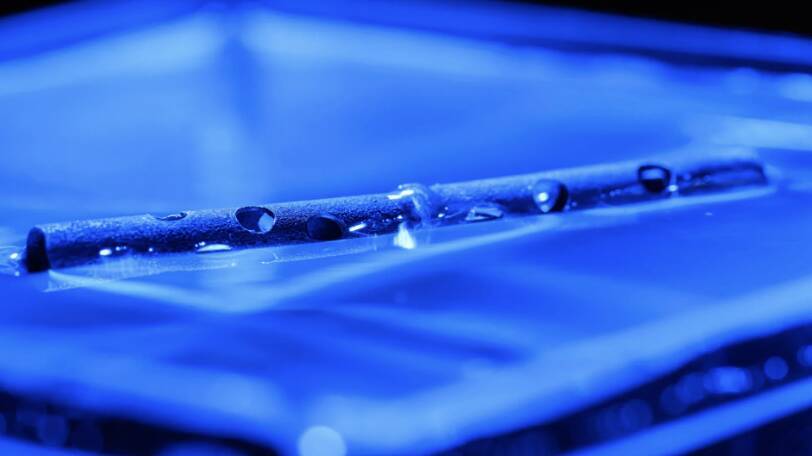

While the development of the buoyant metal tubes is a significant breakthrough, there are still many challenges to overcome before this technology can be widely adopted. One of the main challenges is scaling up the production process to make it more economical and efficient. Currently, the nanopatterning process is relatively expensive and time-consuming, which could limit its adoption in the maritime industry.

Another challenge is the need for further testing and validation of the technology. While the researchers have demonstrated the effectiveness of the buoyant metal tubes in laboratory experiments, they need to be tested in real-world conditions to ensure their safety and reliability. This could involve conducting large-scale experiments or simulations to demonstrate the technology’s effectiveness in a variety of scenarios.

In conclusion, the development of the buoyant metal tubes is a significant breakthrough that could have profound implications for the maritime industry. By creating a highly buoyant metal tube structure that can float even when submerged or damaged, scientists have opened up new possibilities for the design and construction of ships, boats, and other maritime vessels. While there are still many challenges to overcome, the potential benefits of this technology are vast and varied, and it could play a significant role in shaping the future of the maritime industry.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm