Scientists develop metal tubes that could enable unsinkable ships

The concept of unsinkable ships has long been a topic of fascination in the maritime industry. While there have been several attempts to create vessels that can withstand catastrophic damage and remain afloat, none have been entirely successful. However, a recent breakthrough by scientists could potentially revolutionize the field of shipbuilding. By developing a highly buoyant metal tube structure, researchers have created a material that can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to make “unsinkable ships” a reality.

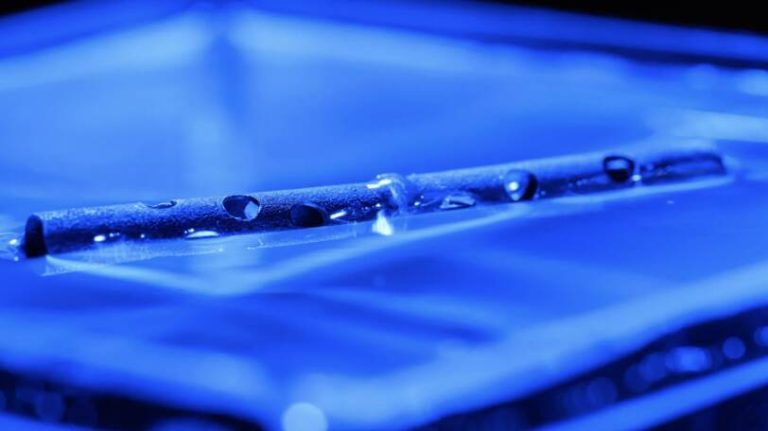

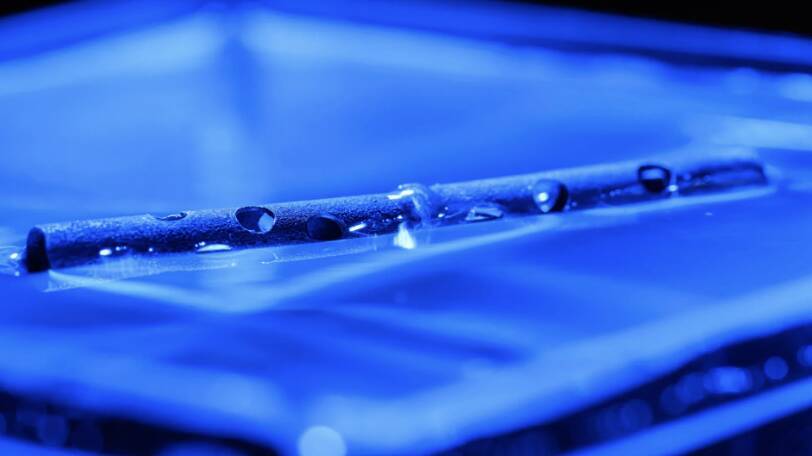

The key to this breakthrough lies in the processing of aluminium, a metal that is commonly used in shipbuilding due to its lightweight and corrosion-resistant properties. By adding nanometer-scale grooves to aluminium tubes, scientists were able to create a superhydrophobic surface that can stably maintain air bubbles on the inner surface. This unique property allows the metal tubes to remain buoyant, even when damaged or submerged in water for extended periods.

The development of this technology is a significant achievement, as it addresses one of the major challenges in creating unsinkable ships. Traditional shipbuilding materials, such as steel and fibreglass, can become waterlogged and lose their buoyancy when damaged. In contrast, the new metal tube structure developed by scientists can maintain its buoyancy, even when holes are drilled into it or it is submerged in water.

The potential applications of this technology are vast and far-reaching. In the maritime industry, unsinkable ships could revolutionize the way vessels are designed and built. No longer would ships need to rely on complex systems and compartments to stay afloat in the event of damage. Instead, they could be constructed with the new metal tube structure, providing a simple and effective solution to the problem of buoyancy.

In addition to its potential use in shipbuilding, this technology could also have applications in other fields, such as offshore oil and gas platforms, and even in the development of new types of submarines. The ability to create structures that can maintain their buoyancy, even when damaged or submerged, could open up new possibilities for exploration and development in the world’s oceans.

The development of this technology is also a testament to the power of interdisciplinary research. By combining materials science, nanotechnology, and engineering, scientists were able to create a material with unique properties that can solve a complex problem. This type of collaborative research is essential for driving innovation and developing new technologies that can address some of the world’s most pressing challenges.

While the development of unsinkable ships is still in its early stages, the potential benefits are clear. With the ability to create vessels that can withstand catastrophic damage and remain afloat, the maritime industry could become safer and more efficient. The economic benefits of such a technology could also be significant, as it could reduce the risk of costly accidents and environmental disasters.

In conclusion, the development of metal tubes that can enable unsinkable ships is a significant breakthrough with far-reaching implications. By creating a highly buoyant metal tube structure, scientists have opened up new possibilities for the maritime industry and beyond. As research continues to advance, it will be exciting to see how this technology is developed and applied in the years to come.

Source:

https://www.sciencedaily.com/releases/2026/01/260130041105.htm