Scientists develop metal tubes that could enable unsinkable ships

The concept of unsinkable ships has long been a topic of interest and research in the field of marine engineering. While various materials and designs have been proposed and developed over the years, a team of scientists has recently made a groundbreaking discovery that could potentially revolutionize the way ships are built. By developing a highly buoyant metal tube structure, these scientists have created a material that can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to make “unsinkable ships” a reality, and its implications are vast and exciting.

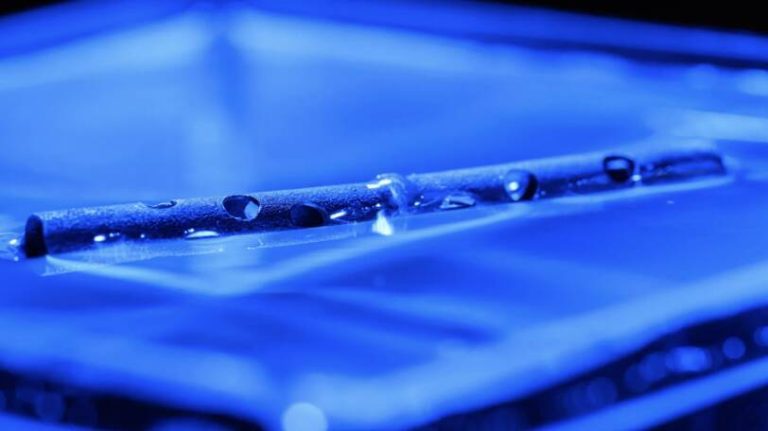

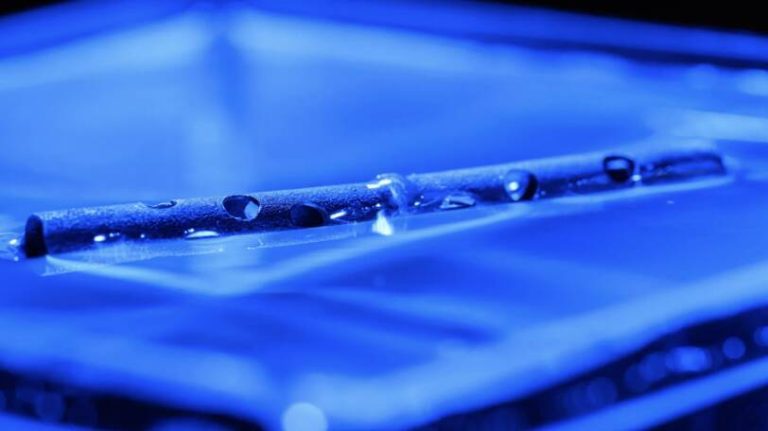

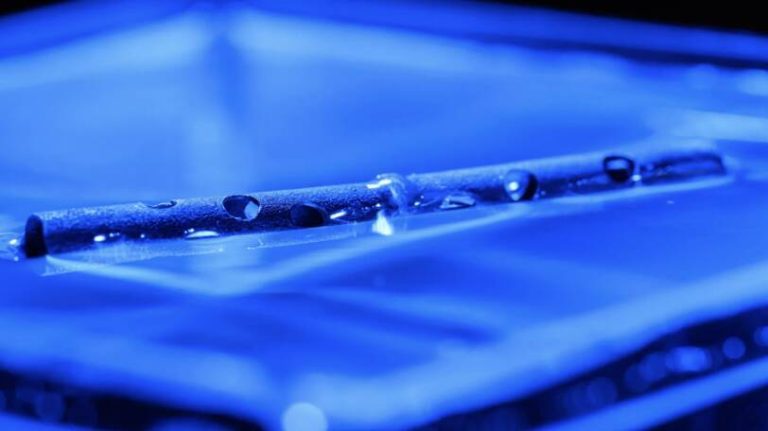

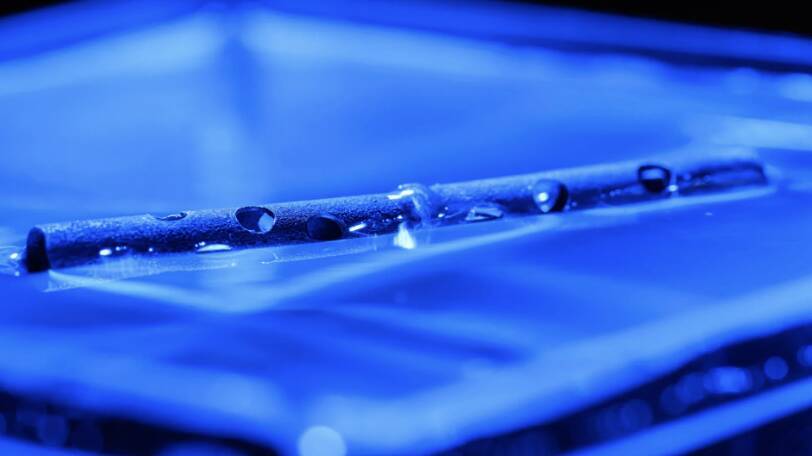

The key to this breakthrough lies in the processing of aluminium, a metal that is commonly used in shipbuilding due to its lightweight and corrosion-resistant properties. However, aluminium is not typically considered a buoyant material, as it is denser than water and tends to sink when submerged. To overcome this limitation, the scientists added nanometer-scale grooves to aluminium tubes, making them superhydrophobic. This means that the surface of the tubes is extremely water-repellent, allowing them to maintain a layer of air bubbles on the inner surface even when submerged in water.

The addition of these nanometer-scale grooves is crucial to the buoyancy of the metal tubes. When the tubes are submerged in water, the air bubbles trapped in the grooves create a layer of air that reduces the density of the material, making it float. This phenomenon is known as the “lotus effect,” named after the lotus leaf, which has a similar self-cleaning and water-repellent property. The scientists’ innovative use of this property has enabled them to create a metal material that can stably maintain air bubbles on its surface, even when damaged or submerged for extended periods.

The potential applications of this technology are vast and exciting. The most obvious use is in the construction of ships, where the buoyant metal tubes could be used to create unsinkable vessels. This would have a significant impact on the safety of passengers and crew, as well as the environment, as it would reduce the risk of oil spills and other accidents. Additionally, the use of these metal tubes could also enable the creation of floating structures, such as offshore platforms, bridges, and even entire cities.

The development of this technology also has significant implications for the shipping industry. With the ability to create unsinkable ships, the risk of accidents and losses at sea would be greatly reduced, resulting in lower insurance costs and increased efficiency. Furthermore, the use of buoyant metal tubes could also enable the creation of more efficient and environmentally friendly ships, as they would be able to withstand harsh weather conditions and reduce the need for heavy ballast.

The scientists’ discovery also has potential applications in other fields, such as aerospace and biomedical engineering. The use of superhydrophobic materials could enable the creation of more efficient and durable aircraft, as well as medical devices that can withstand harsh environments. The possibilities are endless, and it will be exciting to see how this technology is developed and applied in the coming years.

In conclusion, the development of metal tubes that can enable unsinkable ships is a groundbreaking discovery that has the potential to revolutionize the way ships are built and operated. The use of nanometer-scale grooves to create superhydrophobic surfaces has enabled the creation of a highly buoyant metal material that can float even when submerged or damaged. As this technology continues to evolve and improve, we can expect to see significant advancements in the shipping industry, as well as in other fields where durable and efficient materials are essential.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm