Scientists develop metal tubes that could enable unsinkable ships

The concept of an “unsinkable ship” has long been a topic of fascination and debate among scientists, engineers, and maritime enthusiasts. While the idea may have seemed like the stuff of science fiction in the past, recent breakthroughs in materials science have brought us one step closer to making this vision a reality. A team of scientists has made a groundbreaking discovery that could revolutionize the way we design and build ships, by developing a highly buoyant metal tube structure that can float even when submerged for long periods or damaged with holes.

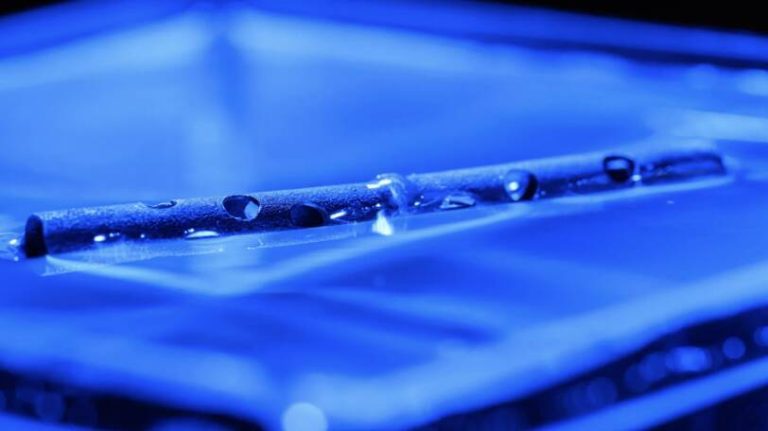

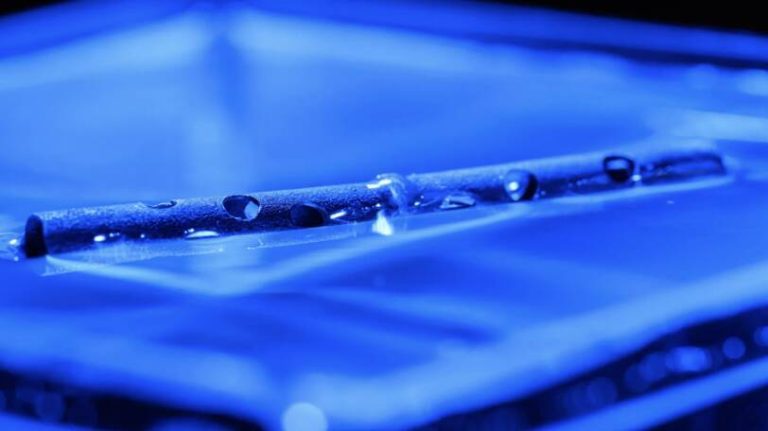

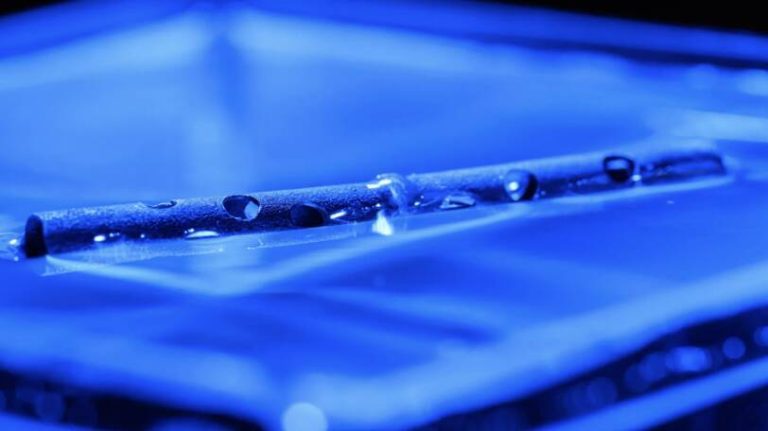

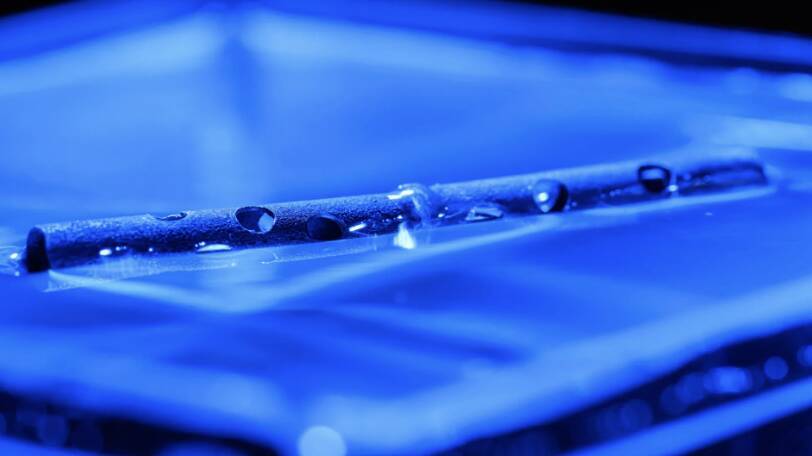

The innovative technology, which involves processing aluminium to create a unique tube structure, has the potential to enable the creation of “unsinkable ships” that can withstand even the most extreme marine conditions. The key to this breakthrough lies in the addition of nanometer-scale grooves to aluminium tubes, which renders them superhydrophobic and capable of stably maintaining air bubbles on the inner surface. This remarkable property allows the metal tubes to remain afloat, even when subjected to significant damage or water pressure.

To understand the significance of this discovery, let’s delve deeper into the science behind it. The researchers began by examining the properties of aluminium, a metal that is commonly used in shipbuilding due to its high strength-to-weight ratio, corrosion resistance, and affordability. However, aluminium is not typically known for its buoyancy, as it is denser than water. To overcome this limitation, the scientists employed a novel approach, using a technique called “nanotexturing” to create tiny grooves on the surface of the aluminium tubes.

These nanometer-scale grooves, which are invisible to the naked eye, have a profound impact on the way the metal interacts with water. By creating a series of tiny, interconnected channels, the grooves enable the formation of a stable layer of air bubbles on the inner surface of the tube. This phenomenon, known as “superhydrophobicity,” allows the aluminium tube to repel water and maintain its buoyancy, even when submerged in water.

The implications of this discovery are profound, with potential applications extending far beyond the realm of shipbuilding. For instance, the development of unsinkable ships could revolutionize the maritime industry, enabling the creation of vessels that can withstand extreme weather conditions, such as hurricanes or tsunamis. This, in turn, could lead to significant improvements in safety, reducing the risk of accidents and fatalities at sea.

Furthermore, the technology could also have a major impact on the offshore oil and gas industry, where platforms and rigs are often vulnerable to damage from harsh marine environments. By incorporating the buoyant metal tubes into the design of these structures, engineers could create more resilient and stable platforms, reducing the risk of accidents and environmental disasters.

In addition to these practical applications, the discovery of superhydrophobic aluminium tubes also has significant scientific implications. The research demonstrates the potential for nanotexturing to create novel materials with unique properties, opening up new avenues for exploration in fields such as materials science and nanotechnology.

As scientists continue to refine and develop this technology, we can expect to see significant advancements in the design and construction of ships, offshore platforms, and other marine structures. The potential for “unsinkable ships” is no longer the stuff of science fiction, but a tangible reality that could transform the maritime industry and beyond.

In conclusion, the development of metal tubes that can float even when submerged or damaged is a groundbreaking discovery that has the potential to revolutionize the way we build and design ships. By harnessing the power of nanotexturing and superhydrophobicity, scientists have created a novel material that could enable the creation of unsinkable ships, offshore platforms, and other marine structures. As we look to the future, it will be exciting to see how this technology evolves and is applied in a wide range of fields.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm