Scientists develop metal tubes that could enable unsinkable ships

The concept of unsinkable ships has long been a topic of fascination and debate in the maritime industry. While significant advancements have been made in ship design and safety features, the risk of sinking remains a concern. However, a recent breakthrough in materials science may revolutionize the way ships are constructed, making them virtually unsinkable. Scientists have developed a highly buoyant metal tube structure by processing aluminium, which can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to transform the shipping industry, saving lives and reducing the environmental impact of maritime accidents.

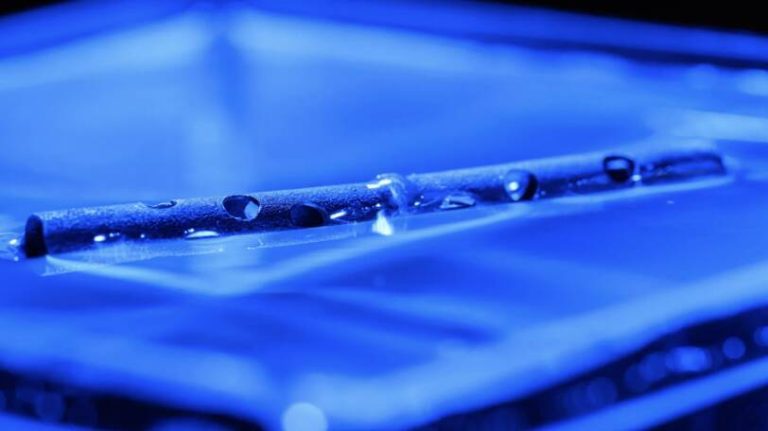

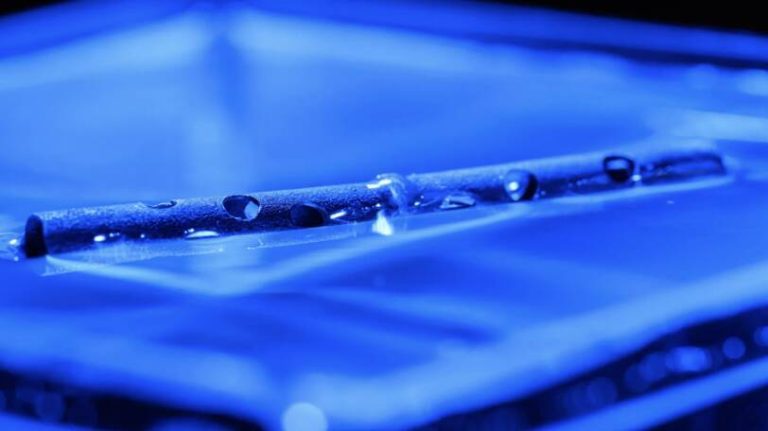

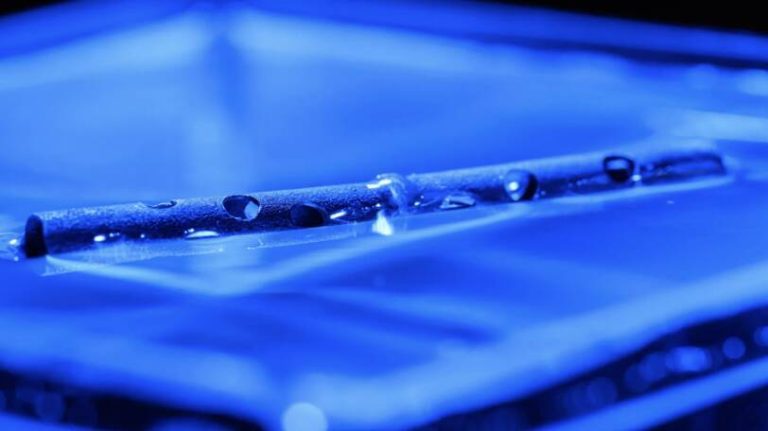

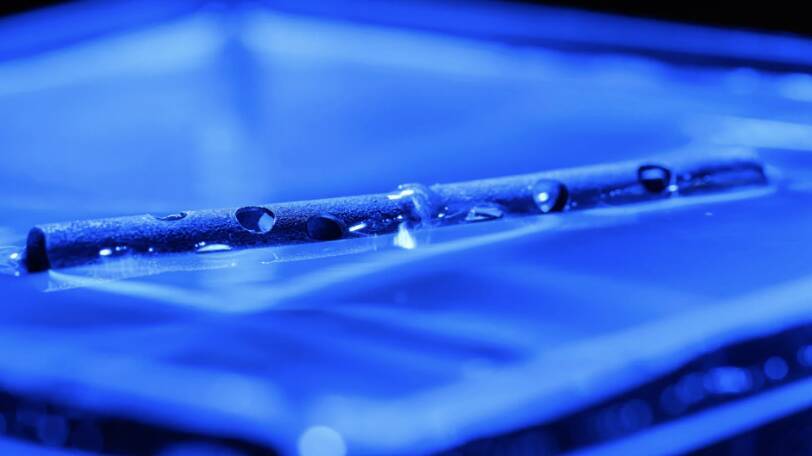

The secret to this groundbreaking technology lies in the addition of nanometer-scale grooves to aluminium tubes, making them superhydrophobic. This unique surface treatment enables the tubes to stably maintain air bubbles on the inner surface, even when submerged in water. As a result, the metal tubes exhibit exceptional buoyancy, allowing them to remain afloat despite being damaged or flooded. The implications of this discovery are profound, as it could lead to the development of ships that can withstand catastrophic damage and remain afloat, even in the most extreme conditions.

The team of scientists behind this innovation used a combination of experimental and theoretical approaches to create the superhydrophobic aluminium tubes. By carefully crafting the surface of the tubes with nanometer-scale grooves, they were able to create a material that defies the conventional properties of metals. The resulting structure is not only incredibly buoyant but also remarkably durable, with the ability to withstand significant damage without compromising its flotation capabilities.

One of the most significant advantages of this technology is its potential to improve ship safety. The ability to create unsinkable ships would revolutionize the maritime industry, reducing the risk of accidents and saving lives. Imagine a world where ships can withstand even the most catastrophic events, such as collisions or explosions, without sinking. The impact on the environment would also be substantial, as the risk of oil spills and other hazardous materials entering the ocean would be significantly reduced.

The potential applications of this technology extend far beyond the shipping industry. The development of superhydrophobic metals could have a significant impact on a wide range of fields, including aerospace, construction, and even biomedical engineering. For example, the creation of lightweight, buoyant materials could lead to the development of more efficient aircraft or spacecraft. In construction, these materials could be used to create buildings that are more resistant to flooding and other forms of water damage.

While the development of unsinkable ships is still in its infancy, the potential benefits are undeniable. As researchers continue to refine and improve this technology, we can expect to see significant advancements in the coming years. The possibility of creating ships that can withstand even the most extreme conditions is a tantalizing prospect, one that could transform the maritime industry and save countless lives.

In conclusion, the development of metal tubes that can enable unsinkable ships is a groundbreaking achievement with far-reaching implications. The creation of superhydrophobic aluminium tubes with nanometer-scale grooves has opened up new possibilities for the maritime industry, with the potential to improve ship safety, reduce environmental risks, and transform the way ships are constructed. As this technology continues to evolve, we can expect to see significant advancements in the coming years, ultimately leading to the creation of unsinkable ships that will revolutionize the shipping industry.

For more information on this breakthrough, please visit: https://www.sciencedaily.com/releases/2026/01/260130041105.htm