Scientists develop metal tubes that could enable unsinkable ships

The concept of unsinkable ships has long been a topic of fascination and debate in the maritime industry. While there have been numerous attempts to create vessels that can withstand even the most catastrophic events, none have been entirely successful. However, a recent breakthrough by scientists may have brought us one step closer to achieving this goal. Researchers have developed a highly buoyant metal tube structure by processing aluminium, which can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to revolutionize the shipbuilding industry and make “unsinkable ships” a reality.

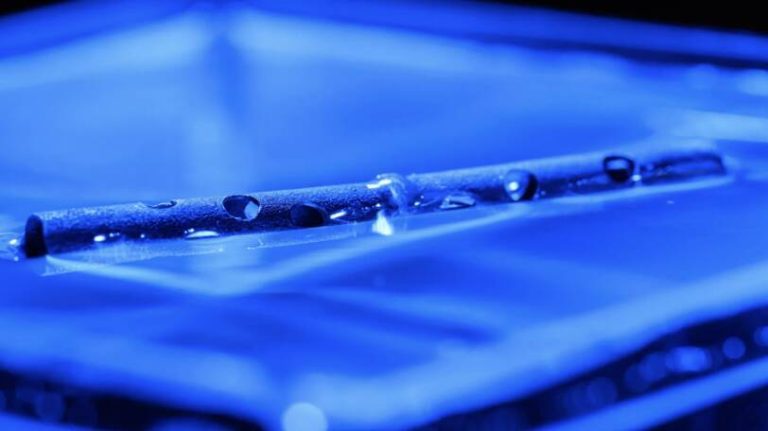

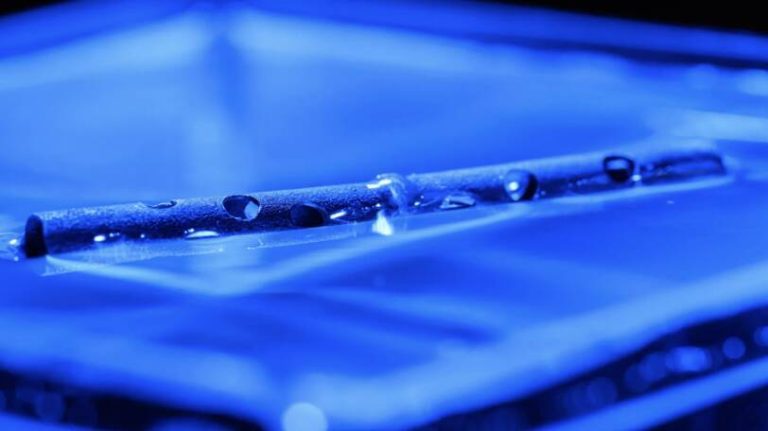

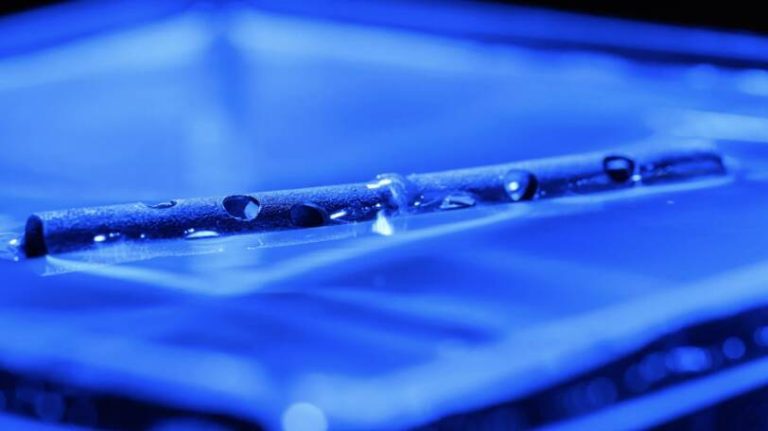

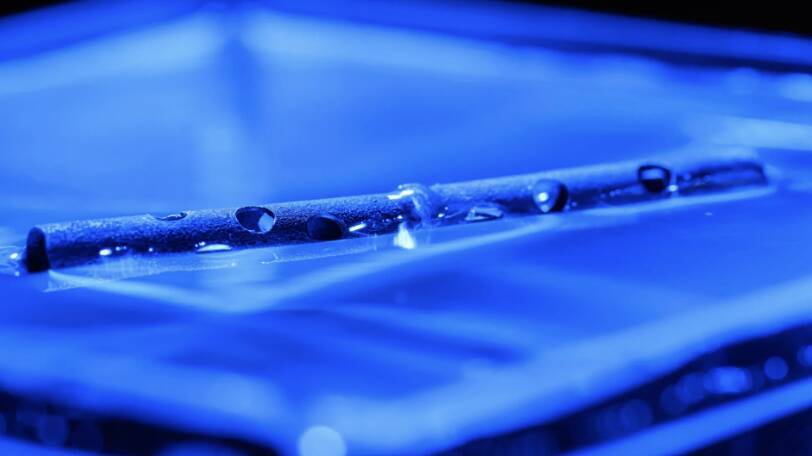

The key to this breakthrough lies in the surface properties of the aluminium tubes. By adding nanometer-scale grooves to the tubes, the scientists were able to make them superhydrophobic, meaning they repel water. This property allows the tubes to stably maintain air bubbles on their inner surface, even when submerged in water. As a result, the tubes are able to retain their buoyancy, even when damaged or punctured.

The researchers’ approach involved creating a unique surface structure on the aluminium tubes, which consists of a series of tiny grooves and ridges. This surface topography creates a barrier between the metal and the surrounding water, preventing the water from penetrating the tube and causing it to sink. The nanometer-scale grooves also help to reduce the surface tension of the water, making it easier for the air bubbles to form and maintain themselves on the inner surface of the tube.

The implications of this technology are significant. If it can be scaled up and applied to the construction of ships, it could potentially make them unsinkable, even in the event of catastrophic damage. This would not only save lives but also reduce the environmental impact of shipwrecks, which can have devastating effects on marine ecosystems.

The potential applications of this technology extend beyond the maritime industry. It could also be used in the development of offshore platforms, buoys, and other marine structures that require high levels of buoyancy and stability. Additionally, the superhydrophobic surface properties of the aluminium tubes could be used to improve the efficiency of heat exchangers, which are used in a wide range of industrial applications.

While this breakthrough is certainly promising, there are still several challenges that need to be overcome before it can be widely adopted. One of the main hurdles is the cost and complexity of producing the nanometer-scale grooves on a large scale. The researchers will need to develop more efficient and cost-effective methods for creating these surface structures, which could involve the use of advanced manufacturing techniques such as 3D printing or laser etching.

Another challenge is ensuring that the superhydrophobic surface properties of the aluminium tubes are durable and long-lasting. The researchers will need to conduct further testing to determine how well the tubes perform in different environmental conditions, such as high temperatures, high pressures, and exposure to corrosive substances.

Despite these challenges, the potential benefits of this technology are too great to ignore. The development of unsinkable ships could have a major impact on the maritime industry, reducing the risk of accidents and environmental disasters. It could also lead to the creation of new types of vessels, such as floating cities or offshore platforms, which could provide innovative solutions to some of the world’s most pressing problems, such as overpopulation and climate change.

In conclusion, the development of metal tubes that can float even when submerged or damaged is a significant breakthrough that could have far-reaching implications for the maritime industry. By creating a superhydrophobic surface structure on aluminium tubes, researchers have been able to make them highly buoyant and resistant to water penetration. While there are still challenges to be overcome, this technology has the potential to revolutionize the way we build ships and other marine structures, making them safer, more efficient, and more sustainable.

For more information on this breakthrough, please visit: https://www.sciencedaily.com/releases/2026/01/260130041105.htm