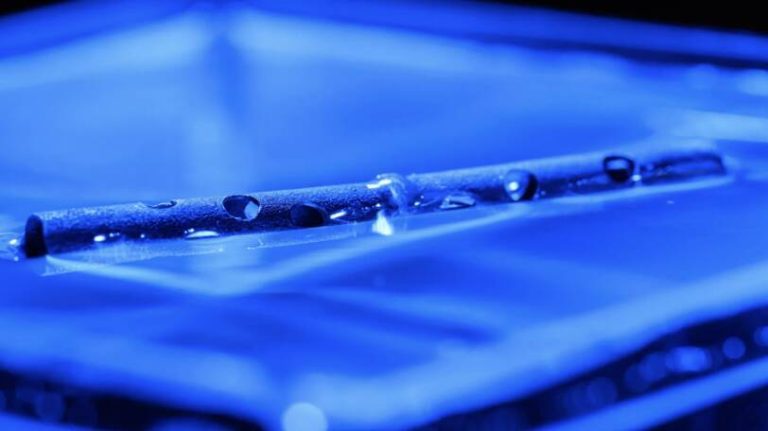

Scientists develop metal tubes that could enable unsinkable ships

The concept of an “unsinkable ship” has long been a topic of fascination and debate among scientists, engineers, and maritime enthusiasts. While the idea of a ship that can withstand any amount of damage or flooding may seem like the stuff of science fiction, a recent breakthrough in materials science may bring us one step closer to making this vision a reality. Scientists have developed a highly buoyant metal tube structure by processing aluminium that can float even when submerged for long periods or damaged with holes. This innovative technology has the potential to revolutionize the maritime industry and could potentially be used to make “unsinkable ships.”

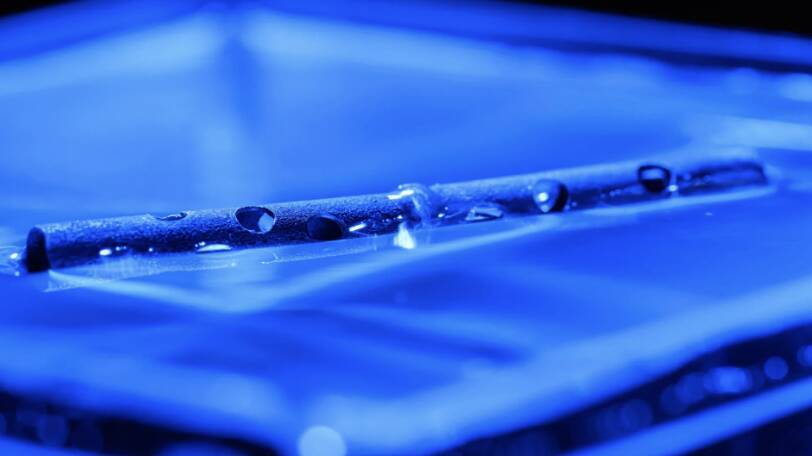

The key to this breakthrough lies in the development of a superhydrophobic (water-repelling) surface on the aluminium tubes. By adding nanometer-scale grooves to the surface of the tubes, the scientists were able to create a material that is not only highly buoyant but also able to stably maintain air bubbles on the inner surface. This unique property allows the tubes to remain afloat even when damaged or submerged for extended periods.

The process of creating these superhydrophobic surfaces involves a complex series of steps. First, the aluminium tubes are treated with a specialized coating that creates a layer of tiny grooves on the surface. These grooves are measured in nanometers, which is equivalent to one billionth of a meter. The grooves are so small that they are invisible to the naked eye, but they play a crucial role in creating the superhydrophobic effect.

Once the grooves have been created, the tubes are then subjected to a process called “anodization,” which involves passing an electric current through the metal to create a thin layer of oxide on the surface. This oxide layer helps to enhance the water-repelling properties of the material, making it even more effective at maintaining air bubbles on the inner surface.

The result of this process is a metal tube structure that is not only highly buoyant but also incredibly durable. The tubes are able to withstand significant damage, including holes and punctures, without losing their ability to float. This makes them ideal for use in a variety of applications, including marine vessels, offshore platforms, and even aerospace technology.

The potential implications of this technology are vast and far-reaching. For example, ships made with these metal tubes could potentially withstand catastrophic damage, such as collisions or explosions, without sinking. This could save countless lives and prevent environmental disasters, such as oil spills. Additionally, the use of these tubes could also enable the creation of more efficient and sustainable marine vessels, such as cargo ships and tankers.

The development of these metal tubes also has significant implications for the aerospace industry. The ability to create lightweight, durable, and buoyant materials could potentially be used to create more efficient and sustainable aircraft, such as seaplanes and hovercraft. This could revolutionize the way we travel and transport goods, making it faster, cheaper, and more environmentally friendly.

In addition to these practical applications, the development of these metal tubes also has significant scientific implications. The creation of superhydrophobic surfaces is a complex and challenging process, and the discovery of new methods for creating these surfaces could lead to breakthroughs in a variety of fields, including materials science, physics, and chemistry.

In conclusion, the development of metal tubes that can enable “unsinkable ships” is a significant breakthrough with far-reaching implications for the maritime and aerospace industries. The use of superhydrophobic surfaces and nanometer-scale grooves has created a material that is not only highly buoyant but also incredibly durable and resistant to damage. As this technology continues to evolve and improve, we can expect to see significant advances in the creation of more efficient, sustainable, and safe marine vessels and aircraft.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm