Scientists develop metal tubes that could enable unsinkable ships

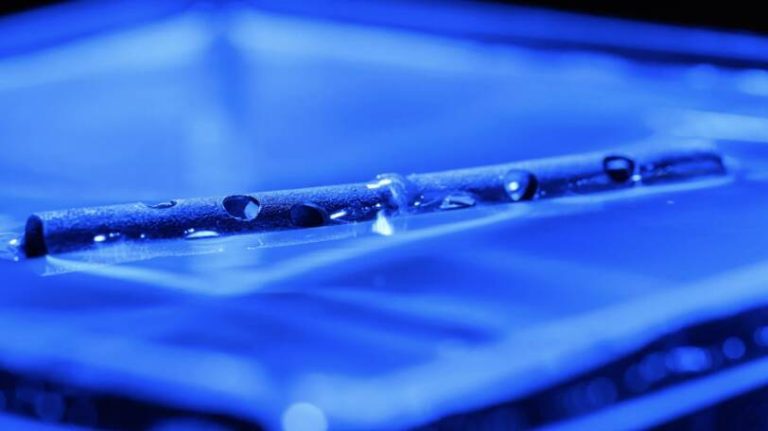

The concept of unsinkable ships has long been a topic of interest and debate in the maritime industry. While significant advancements have been made in ship design and safety features, the risk of sinking still exists, especially in extreme weather conditions or in the event of a catastrophic accident. However, a recent breakthrough in materials science may revolutionize the way ships are built, making them virtually unsinkable. Scientists have developed a highly buoyant metal tube structure by processing aluminum that can float even when submerged for long periods or damaged with holes.

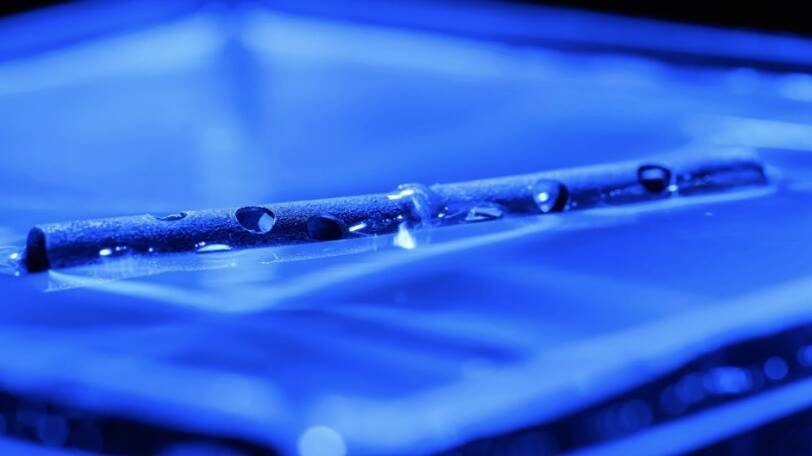

The innovative technology involves adding nanometer-scale grooves to aluminum tubes, making them superhydrophobic and able to stably maintain air bubbles on the inner surface. This unique property allows the metal tubes to retain their buoyancy, even when damaged or submerged in water for extended periods. The implications of this discovery are significant, as it could potentially be used to make ships that are resistant to sinking, even in the most extreme conditions.

The development of this technology is the result of a collaborative effort between materials scientists and engineers, who have been working to create new materials with enhanced properties. By manipulating the surface structure of aluminum tubes at the nanoscale, the researchers were able to create a material that is not only lightweight and strong but also highly buoyant. The addition of nanometer-scale grooves to the surface of the tubes creates a unique texture that repels water, allowing air bubbles to form and remain stable on the inner surface of the tubes.

The potential applications of this technology are vast and varied. One of the most significant advantages of this material is its ability to maintain its buoyancy, even when damaged or submerged in water for extended periods. This property makes it an ideal material for use in shipbuilding, where safety and reliability are paramount. The use of these metal tubes in ship construction could potentially reduce the risk of sinking, even in extreme weather conditions or in the event of a catastrophic accident.

In addition to its potential use in shipbuilding, this technology could also have applications in other industries, such as aerospace and energy. For example, the use of these metal tubes in the construction of offshore oil rigs or wind turbines could provide a safer and more reliable way to operate in harsh marine environments. The material’s ability to maintain its buoyancy and stability, even in extreme conditions, makes it an attractive option for use in a wide range of applications.

The development of this technology is also significant from an environmental perspective. The use of unsinkable ships could potentially reduce the risk of oil spills and other environmental disasters, which can have devastating consequences for marine ecosystems. By reducing the risk of sinking, ships can be designed to be more environmentally friendly, with a lower risk of causing harm to the environment.

While the development of this technology is a significant breakthrough, there are still many challenges to be overcome before it can be widely adopted. One of the main challenges is scaling up the production of these metal tubes, which is currently a complex and time-consuming process. Additionally, the cost of production is still relatively high, making it less competitive with traditional materials.

Despite these challenges, the potential benefits of this technology make it an exciting and promising area of research. As scientists and engineers continue to develop and refine this material, we can expect to see significant advancements in the field of materials science. The possibility of creating unsinkable ships is no longer a distant dream, but a tangible reality that could revolutionize the maritime industry.

In conclusion, the development of highly buoyant metal tubes by processing aluminum is a significant breakthrough that could potentially enable the creation of unsinkable ships. The unique properties of this material, including its ability to maintain air bubbles on the inner surface, make it an ideal option for use in shipbuilding and other industries. While there are still challenges to be overcome, the potential benefits of this technology make it an exciting and promising area of research. As we continue to develop and refine this material, we can expect to see significant advancements in the field of materials science and a safer, more reliable maritime industry.

News source: https://www.sciencedaily.com/releases/2026/01/260130041105.htm